Welcome To Know Our Products, We Can Offer You High Quality Products!

How is the quality of rubber seals controlled?

2023-05-05

The application range of silicone products is very wide, because it is both non-toxic and environmentally friendly, and does not depend on petroleum resources, so there are silicone products in all aspects of our lives, so under what circumstances will it affect the quality of silicone products? .

1. The quality of silicone raw materials: The quality of raw materials will make it difficult to disassemble silicone products. The toughness of poor-quality silicone raw materials is insufficient and the tear strength is obviously insufficient. It must be difficult to disassemble the edges during the process of disassembly.

2. In the molding process: the product is formed relatively thickly, so the raw edges are actually thicker than the silicone products, and the increase in thickness will definitely lead to the difficulty of removing the edges.

3. Problems with the forming mold: If the design of the mold's self-disassembly is unreasonable, the use of the forming mold is too long, and the quality of the forming mold is not good, these conditions will make it difficult to disassemble the edges after the production is formed.

4. Environmental factors for vulcanization: The vulcanization temperature should be appropriate. Problems that are too high or too low will make it difficult to remove the edges. At the same time, the vulcanization time also needs to be well controlled. Too long vulcanization time will cause the product to become brittle, and too short vulcanization time will cause the vulcanization link to be ineffective. Silicone product factories must control the vulcanization link well.

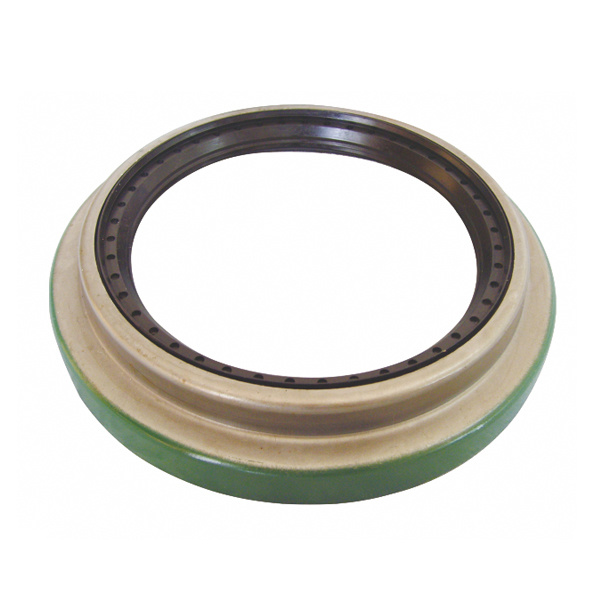

The correct way to choose rubber seals is:.

1. Direction of movement-First determine the direction of movement of the seal where it is located, such as reciprocating, rotating, spiral or fixed.

2. Sealing focus-for example, it is determined that the active point is the rod seal of the inner diameter or the active point is the piston seal of the outer diameter.

3. Temperature level-Check the instructions for the use of the original machinery or evaluate the working temperature according to the actual working environment to determine the required utilization information. Silicone products have an open porous structure and can adsorb many rubber products. It is a good desiccant, adsorbent and catalyst carrier. The adsorption effect of silicone is mainly physical adsorption. It can be regenerated and used repeatedly. Add acid to an alkali metal silicate (such as sodium silicate) solution to acidify it, and then add a certain amount of electrolyte for stirring to generate a silicate gel, or add acid or ammonium salt to a thicker sodium silicate solution to generate a silicate gel.

4. Pressure level-Check the relevant data from the original mechanical use instructions, or infer the working pressure level by looking at the hardness and structure of the original seal.

Silicone products

RELEVANT INFORMATION

How is the quality of rubber seals controlled?

2023-05-05

Analysis of possible production problems and causes of silicone O-rings

2023-05-05

Transportation and assembly of oil seals

2023-05-05