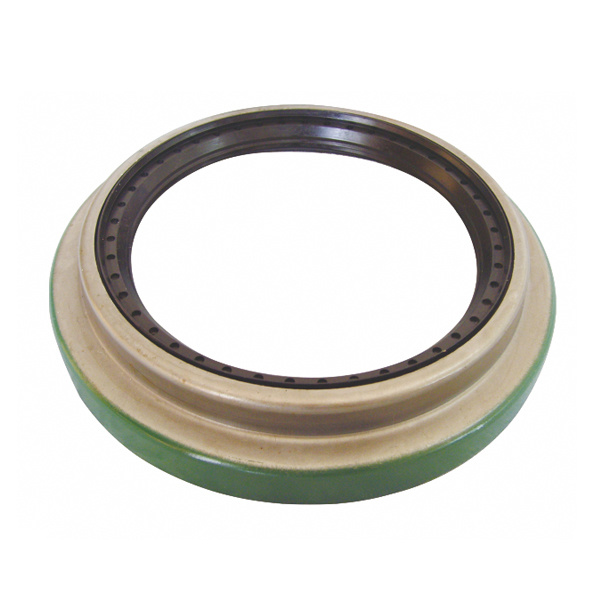

Welcome To Know Our Products, We Can Offer You High Quality Products!

Transportation and assembly of oil seals

2023-05-05

1. Transportation and storage of oil seals

1. Do not open the original packaging, pay attention to whether the packaging is damaged, and try to leave the oil seal in the original packaging before assembly.;

2. Avoid direct sunlight and do not place it near a high-temperature heat source, as this will cause the rubber to age.;

3. The oil seal shall not be scattered at will. Pay attention to dust and soil protection to ensure that the oil seal is in a closed or covered state.;

4. When transporting and using the oil seal, in order to prevent the deformation of the oil seal and the spring from falling off, please do not give excessive impact.;

5. The oil seal should not be tied with string, nor should it be hung on nails or metal wires, which will damage the sealing lip.;

6. Do not put the oil seal in a damp place, this will rust the metal parts.;

7. Do not put the seal close to the TV and ozone-producing place;

8. Please do not rub the end of the lip with nails or hard objects to prevent damage to the sealing lip.;

Assembly of oil seals

2. The assembly of the oil seal, no matter how suitable the design of the installation part of the oil seal and the choice of the oil seal are, if the assembly is rough, it will not be able to give full play to the predetermined function of the oil seal.

1. When the oil seal is installed, the outer surface should be coated with appropriate lubricant, the lips should be coated with suitable cleaning grease, and the oil seal with dust-proof lips should be filled with suitable cleaning grease between the main lips before assembly.

2. Place the end of the sealing lip of the oil seal towards the side of the sealing medium, and avoid reverse assembly.

3. When the oil package enters the seat hole, special tools should be used to push it in to prevent the position from skew.

4. Various measures should be taken to prevent lip damage at the threads, keyways, spline, etc. through the lip of the oil seal, and special tools should be used to assemble it.

5. The oil seal should be placed horizontally in the seat hole and pressurized evenly. Do not tilt to force it forward.

Technological

RELEVANT INFORMATION

How is the quality of rubber seals controlled?

2023-05-05

Analysis of possible production problems and causes of silicone O-rings

2023-05-05

Transportation and assembly of oil seals

2023-05-05