Welcome To Know Our Products, We Can Offer You High Quality Products!

Why Choose PU Oil Seals for Maximum Engine Efficiency?

2024-12-30

Why Choose PU Oil Seals for Maximum Engine Efficiency?

In the pursuit of **maximum engine efficiency**, the choice of materials plays a crucial role. Among these materials, **Polyurethane (PU) oil seals** have emerged as a leading option for automotive applications. This article delves into the benefits of PU oil seals, their construction, how they enhance engine performance, and why they should b

Why Choose PU Oil Seals for Maximum Engine Efficiency?

In the pursuit of **maximum engine efficiency**, the choice of materials plays a crucial role. Among these materials, **Polyurethane (PU) oil seals** have emerged as a leading option for automotive applications. This article delves into the benefits of PU oil seals, their construction, how they enhance engine performance, and why they should be your go-to choice for ensuring optimal engine function.

Understanding Oil Seals: The Basics

Oil seals, also known as **shaft seals**, are critical components in an engine. They serve to seal the lubricants within the engine, preventing leaks and contamination from external elements. This is vital for maintaining the engine's overall health and performance.

The Importance of Oil Seals in Engine Function

The engine is a complex system where precision matters. Oil seals maintain the integrity of the engine oil, ensuring that it remains free from contaminants. This purity is essential for:

- Reducing friction between moving parts

- Enhancing fuel efficiency

- Prolonging engine life

Traditional vs. PU Oil Seals: A Comparative Analysis

Traditionally, oil seals were made from materials such as rubber or nitrile. While these materials have served their purpose, they fall short in several areas compared to PU oil seals.

**Key Differences:**

1. **Durability**: PU oil seals are more resistant to wear and tear, thereby extending their lifespan.

2. **Temperature Resistance**: PU can withstand higher temperatures without deforming, making it suitable for high-performance engines.

3. **Chemical Resistance**: PU oil seals are less susceptible to degradation from chemicals present in engine oils, ensuring long-term performance.

Benefits of PU Oil Seals

Choosing PU oil seals offers numerous advantages that contribute to **maximum engine efficiency**.

1. Enhanced Sealing Performance

PU oil seals provide superior sealing capabilities. Their design allows for a tighter fit around the shaft, minimizing the risk of leaks. This tight seal helps maintain consistent oil pressure within the engine, which is crucial for efficient lubrication.

2. Improved Wear Resistance

The wear resistance of PU oil seals is unmatched. They exhibit a high tolerance to friction and can withstand the constant motion of the engine components. This durability translates to fewer replacements and maintenance costs over time.

3. Temperature Tolerance

Engines generate a significant amount of heat, and PU oil seals are engineered to tolerate high temperatures. This characteristic prevents the seals from melting or becoming brittle, ensuring they perform optimally even under extreme conditions.

4. Chemical Stability

PU oil seals can resist various chemicals, including acids and fuels, which might otherwise degrade traditional seal materials. This chemical stability ensures that the oil seals maintain their integrity throughout their lifespan.

5. Versatility in Application

PU oil seals can be used in a wide range of applications beyond just automotive engines. They are effective in industrial machinery, aerospace applications, and more, showcasing their versatility.

How PU Oil Seals Contribute to Engine Efficiency

To fully understand why PU oil seals are the ideal choice for maximizing engine performance, we must explore their role in engine mechanics.

1. Maintaining Lubrication

Effective lubrication is essential for the smooth operation of engine components. PU oil seals help retain oil within the engine, preventing leaks that could lead to oil starvation and increased friction.

2. Reducing Friction and Heat Generation

By maintaining optimal lubrication levels, PU oil seals reduce friction between moving parts. This decrease in friction not only minimizes wear but also lowers the heat generated within the engine, leading to better overall efficiency.

3. Preventing Contaminant Ingress

PU oil seals act as barriers to contaminants such as dirt, dust, and moisture. By keeping these harmful particles out of the engine, PU seals promote cleaner oil and reduce the risk of engine wear and damage.

Installation and Maintenance of PU Oil Seals

Proper installation and maintenance are crucial for maximizing the benefits of PU oil seals.

1. Installation Best Practices

- **Surface Preparation**: Clean the sealing surfaces thoroughly to ensure a good fit.

- **Use Lubricants**: Apply a thin layer of lubricant to the seal during installation to facilitate easy fitting.

- **Check Compatibility**: Ensure that the PU oil seal is compatible with your engine type.

2. Regular Inspections

Regular inspections can help identify any signs of wear or leakage early. Check for:

- Oil leaks around the seal

- Signs of wear on the seal material

- Misalignment of components

3. Replacement Timing

While PU oil seals are durable, they will eventually need replacement. It’s advisable to replace oil seals during routine maintenance or if any signs of degradation are present.

Frequently Asked Questions (FAQs)

1. What are PU oil seals made of?

PU oil seals are made from polyurethane, a material known for its durability and resistance to wear, heat, and chemicals.

2. How long do PU oil seals last?

With proper maintenance and usage in appropriate conditions, PU oil seals can last several years, often longer than traditional rubber seals.

3. Can I use PU oil seals in any vehicle?

While PU oil seals are versatile, it's essential to ensure compatibility with your specific engine type and application.

4. Are PU oil seals more expensive than traditional seals?

While PU oil seals may have a higher upfront cost, their durability and longevity can lead to overall savings in maintenance and replacement costs.

5. What are the signs of a failing oil seal?

Common signs of a failing oil seal include oil leaks, decreased engine performance, and unusual noises from the engine compartment.

Conclusion

Choosing PU oil seals for your vehicle's engine is a decision that pays off in terms of performance and efficiency. Their superior sealing capabilities, enhanced wear resistance, and ability to withstand extreme conditions make them an ideal choice for any automotive application. By investing in PU oil seals, you not only extend the lifespan of your engine but also enhance its overall efficiency. Transitioning to PU oil seals is a step towards ensuring long-term engine health, making them the smart choice for automotive enthusiasts and professionals alike.

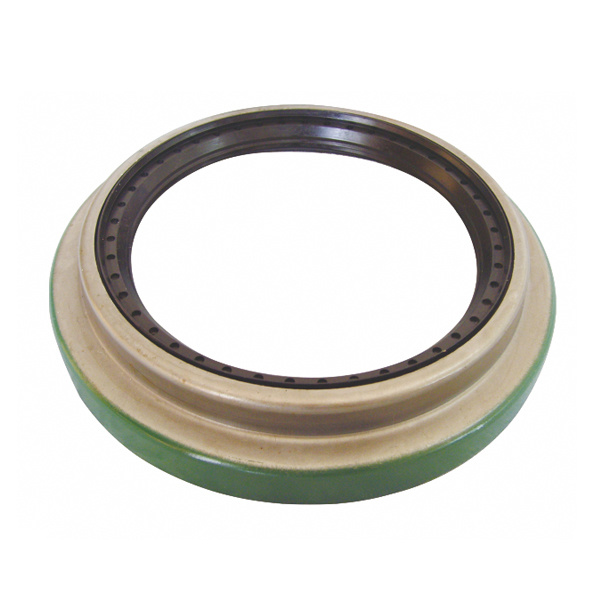

PU oil seal

RELEVANT INFORMATION

How is the quality of rubber seals controlled?

2023-05-05

The application range of silicone products is very wide, because it is both non-toxic and environmentally friendly, and does not depend on petroleum resources, so there are silicone products in all aspects of our lives, so under what circumstances will it affect the quality of silicone products? .

Analysis of possible production problems and causes of silicone O-rings

2023-05-05

Silicone O-shaped sealing ring is a kind of rubber ring with silicone as raw material and a circular cross-section. Because its cross-section is O-shaped, it is called silicone O-shaped sealing ring.

Transportation and assembly of oil seals

2023-05-05

Do not open the original packaging, pay attention to whether the packaging is damaged, and try to leave the oil seal in the original packaging before assembly.;