Welcome To Know Our Products, We Can Offer You High Quality Products!

Low Friction Valve Stem Seals: Enhancing Reliability and Durability in Industrial Applications

2025-06-22

Low Friction Valve Stem Seals: Enhancing Reliability and Durability in Industrial Applications

Table of Contents

1. Introduction to Low Friction Valve Stem Seals

2. Understanding the Importance of Valve Stem Seals

3. Benefits of Low Friction Valve Stem Seals

3.1 Improved Performance and Efficiency

3.2 Enhanced Durability and Longevity

3.3 Reduced Wear and Tear

4. Key Materials Used

Low Friction Valve Stem Seals: Enhancing Reliability and Durability in Industrial Applications

Table of Contents

1. Introduction to Low Friction Valve Stem Seals

2. Understanding the Importance of Valve Stem Seals

3. Benefits of Low Friction Valve Stem Seals

3.1 Improved Performance and Efficiency

3.2 Enhanced Durability and Longevity

3.3 Reduced Wear and Tear

4. Key Materials Used in Low Friction Valve Stem Seals

4.1 PTFE (Polytetrafluoroethylene)

4.2 Nitrile Rubber

4.3 Silicone

5. Installation Techniques for Optimal Performance

5.1 Preparing the Valve Housing

5.2 Proper Seal Placement

5.3 Testing for Leaks

6. Maintenance Tips for Longevity

6.1 Routine Inspections

6.2 Lubrication Practices

7. Common Applications of Low Friction Valve Stem Seals

8. FAQs About Low Friction Valve Stem Seals

9. Conclusion

1. Introduction to Low Friction Valve Stem Seals

In the world of industrial applications, the reliability and efficiency of equipment play a crucial role in operational success. One of the key components enhancing performance is the low friction valve stem seal. These seals are engineered to minimize friction between the valve stem and the seal, ensuring smooth operation while preventing leaks. Our exploration into low friction valve stem seals will reveal their significance, benefits, and practical applications in various industries.

2. Understanding the Importance of Valve Stem Seals

Valve stem seals serve a vital function in controlling the flow of fluids and gases within valves. They ensure that the valve operates smoothly while preventing any leakage that could compromise performance. In many industrial settings, even minor leaks can lead to significant losses in efficiency, safety hazards, and increased operational costs. Low friction valve stem seals are designed to provide optimal sealing while minimizing resistance during operation, making them an essential choice for industries that demand precision.

3. Benefits of Low Friction Valve Stem Seals

Low friction valve stem seals offer numerous advantages over traditional sealing solutions.

3.1 Improved Performance and Efficiency

By reducing friction during operation, low friction valve stem seals enhance the performance of valves. This results in quicker response times and improved efficiency, which are vital in industries such as oil and gas, automotive, and manufacturing.

3.2 Enhanced Durability and Longevity

Made from high-quality materials, low friction valve stem seals tend to exhibit superior wear resistance. This durability means that they can withstand harsh operating conditions without significant degradation, leading to extended service life and reduced replacement costs.

3.3 Reduced Wear and Tear

The low friction characteristic of these seals minimizes the wear and tear on both the valve stem and the seal itself. This translates into fewer maintenance requirements and lower operational disruptions, further contributing to a more efficient workflow.

4. Key Materials Used in Low Friction Valve Stem Seals

The performance of low friction valve stem seals largely depends on the materials used in their construction. Here are some of the primary materials:

4.1 PTFE (Polytetrafluoroethylene)

PTFE is known for its exceptional chemical resistance and low friction properties. It is often used in high-temperature applications, making it ideal for various industrial environments.

4.2 Nitrile Rubber

Nitrile rubber seals are often employed due to their excellent resistance to oil and fuel, providing reliable performance in automotive and machinery applications.

4.3 Silicone

Silicone seals are known for their flexibility and temperature resistance. They are particularly useful in applications that involve varying temperature ranges.

5. Installation Techniques for Optimal Performance

Proper installation of low friction valve stem seals is critical to achieving their full potential in performance.

5.1 Preparing the Valve Housing

Before installation, ensure that the valve housing is clean and free from debris. Any contaminants can compromise the seal's effectiveness.

5.2 Proper Seal Placement

Carefully place the seal into the designated groove, ensuring that it is seated evenly. Misalignment can lead to premature wear and leaks.

5.3 Testing for Leaks

After installation, conduct a thorough leak test. Checking for leaks ensures that the seal is working correctly and contributes to operational efficiency.

6. Maintenance Tips for Longevity

To maximize the lifespan of low friction valve stem seals, regular maintenance is essential.

6.1 Routine Inspections

Perform regular inspections to identify any signs of wear or damage. Early detection can prevent costly replacements and downtime.

6.2 Lubrication Practices

Utilizing the right lubricants can significantly enhance the seal's performance. Ensure that lubricants are compatible with the seal materials to avoid degradation.

7. Common Applications of Low Friction Valve Stem Seals

Low friction valve stem seals find their applications across various industries, including:

- **Oil and Gas**: Ensuring safety and efficiency in drilling operations.

- **Automotive**: Enhancing engine performance and fuel efficiency.

- **Manufacturing**: Supporting machinery that requires precision and reliability.

- **Aerospace**: Meeting stringent safety and performance regulations.

8. FAQs About Low Friction Valve Stem Seals

What are low friction valve stem seals made of?

Low friction valve stem seals are typically made from materials like PTFE, nitrile rubber, and silicone, each selected for its specific properties and application suitability.

How do I know when to replace my valve stem seals?

Signs of wear or damage, such as leaks or decreased valve performance, indicate that it may be time to replace your valve stem seals.

Can low friction valve stem seals be used in high-temperature applications?

Yes, many low friction valve stem seals are designed to withstand high temperatures, particularly those made from PTFE and silicone.

What maintenance is required for low friction valve stem seals?

Regular inspections and proper lubrication are essential to ensure the longevity and effectiveness of low friction valve stem seals.

Are there specific industries that benefit the most from low friction valve stem seals?

Industries such as oil and gas, automotive, manufacturing, and aerospace significantly benefit from the enhanced performance and reliability offered by low friction valve stem seals.

9. Conclusion

Low friction valve stem seals are an indispensable component in various industrial applications, offering improved performance, enhanced durability, and reduced maintenance costs. By understanding their benefits, materials, and proper installation techniques, we can ensure that these seals continue to deliver reliability and durability in our operations. Investing in low friction valve stem seals is not just a choice; it's a commitment to efficiency and longevity in the demanding world of industrial equipment.

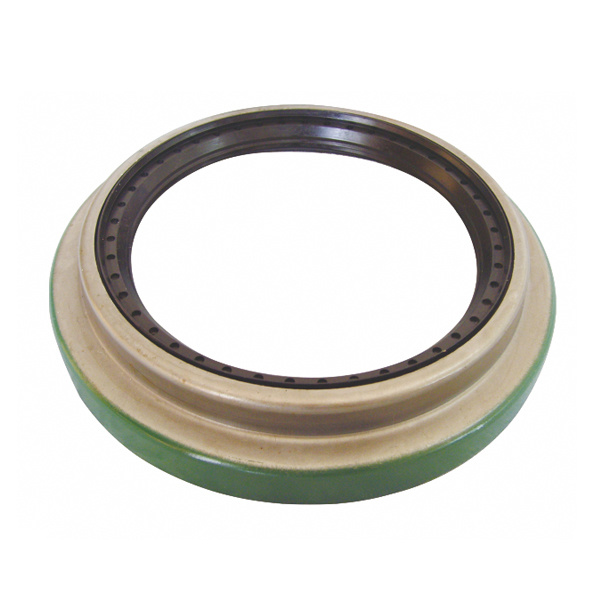

Low Friction Valve Stem Seal

RELEVANT INFORMATION

How is the quality of rubber seals controlled?

2023-05-05

The application range of silicone products is very wide, because it is both non-toxic and environmentally friendly, and does not depend on petroleum resources, so there are silicone products in all aspects of our lives, so under what circumstances will it affect the quality of silicone products? .

Analysis of possible production problems and causes of silicone O-rings

2023-05-05

Silicone O-shaped sealing ring is a kind of rubber ring with silicone as raw material and a circular cross-section. Because its cross-section is O-shaped, it is called silicone O-shaped sealing ring.

Transportation and assembly of oil seals

2023-05-05

Do not open the original packaging, pay attention to whether the packaging is damaged, and try to leave the oil seal in the original packaging before assembly.;