Welcome To Know Our Products, We Can Offer You High Quality Products!

How V Fabric Oil Seals Enhance Performance in Forestry Equipment

2025-07-12

How V Fabric Oil Seals Enhance Performance in Forestry Equipment

In the ever-evolving world of forestry equipment, maintaining optimal performance is crucial. One of the key components that contribute to this performance is the seal. **V Fabric Oil Seals** have emerged as a game-changer, providing not only protection but also enhancing overall machinery efficiency. This article delves into the importance of V Fabric Oil Seals, their applications, and the technological advancements that make them indispensable in the forestry industry.

Table of Contents

- Understanding V Fabric Oil Seals

- Benefits of V Fabric Oil Seals

- Applications in Forestry Equipment

- Technological Advancements in Seal Design

- Performance Enhancements Through Oil Seals

- Maintenance and Longevity of V Fabric Oil Seals

- Case Studies: Success Stories

- Frequently Asked Questions

- Conclusion

Understanding V Fabric Oil Seals

V Fabric Oil Seals are specialized sealing solutions designed to prevent leakage in machinery. Their design incorporates a V-shaped cross-section that allows for effective sealing under various operating conditions. Unlike traditional seals, **V Fabric Oil Seals** can handle extreme temperatures, pressures, and the presence of contaminants, making them ideal for forestry equipment.

The materials used in the construction of these seals typically include high-grade fabric combined with rubber compounds, enabling them to withstand harsh environments while maintaining flexibility and durability. This unique composition is what sets V Fabric Oil Seals apart from other sealing technologies.

Material Composition and Design

The effectiveness of V Fabric Oil Seals is largely attributed to their material composition. High-quality fabrics, such as polyester or nylon, are often combined with elastomers like nitrile or silicone. This combination offers excellent abrasion resistance and low compression set, ensuring that the seals maintain their shape and effectiveness over time.

The V-shaped design not only facilitates better seating in the housing but also allows for easier installation, thereby reducing downtime during maintenance. This engineering innovation is crucial for forestry operations where equipment reliability is paramount.

Benefits of V Fabric Oil Seals

The advantages of using V Fabric Oil Seals in forestry equipment are substantial. Enhanced performance translates to increased productivity, reduced maintenance costs, and improved longevity of machinery.

1. Enhanced Sealing Performance

V Fabric Oil Seals provide superior sealing capabilities, which significantly reduces the risk of leaks. This is especially important in forestry, where the machinery often operates in rugged conditions. By effectively sealing the oil within hydraulic systems and gearboxes, these seals prevent contamination and ensure smooth operation.

2. Increased Equipment Longevity

By preventing leaks and eliminating the ingress of contaminants, V Fabric Oil Seals contribute to the extended lifespan of equipment. This longevity is vital for forestry operations, where equipment is a significant investment. Regular maintenance and the use of high-quality seals can lead to lower total cost of ownership over the equipment's lifetime.

3. Reduced Maintenance Intervals

With V Fabric Oil Seals in place, the frequency of maintenance checks can be reduced. As these seals effectively manage oil and contamination, less downtime is needed for repairs and replacements. This not only saves time but also allows for more efficient allocation of resources within forestry operations.

Applications in Forestry Equipment

V Fabric Oil Seals find applications in a variety of forestry machinery, including:

1. Harvesters

In harvesters, V Fabric Oil Seals protect hydraulic systems and gearboxes from leaks while ensuring efficient power transfer. This is crucial for maintaining the performance of cutting and gathering mechanisms.

2. Skidders

Skidders face unique challenges due to their operation in muddy and wet environments. **V Fabric Oil Seals** effectively prevent moisture ingress, ensuring that the machinery remains functional and efficient.

3. Chippers and Grinders

These machines require robust sealing solutions to handle the high-speed operations and potential debris exposure. V Fabric Oil Seals offer the necessary durability, allowing for uninterrupted performance.

Technological Advancements in Seal Design

Innovation in seal technology continues to drive improvements in performance and reliability. Recent advancements in material science and manufacturing processes have resulted in even more efficient **V Fabric Oil Seals**.

1. Advanced Material Technologies

The development of new rubber compounds that offer greater resistance to temperature and chemicals has significantly enhanced the performance of V Fabric Oil Seals. These materials are engineered to withstand the specific challenges faced in forestry applications.

2. Precision Manufacturing Techniques

Modern manufacturing techniques, such as computer-aided design (CAD) and precision molding, ensure that each seal meets stringent quality standards. This precision leads to better fit and function, reducing the likelihood of seal failure.

Performance Enhancements Through Oil Seals

The integration of V Fabric Oil Seals in forestry equipment leads to noticeable performance enhancements. Understanding these benefits can aid in making informed decisions regarding equipment maintenance and upgrades.

1. Improved Operational Efficiency

By drastically reducing the chances of oil leaks and contamination, V Fabric Oil Seals contribute to smoother operations and better overall efficiency. This allows forestry equipment to function optimally, achieving higher output levels.

2. Environmental Protection

Another significant advantage of using V Fabric Oil Seals is their contribution to environmental protection. By preventing oil leaks, these seals help to minimize the risk of soil and water contamination, which is a critical consideration in forestry operations.

Maintenance and Longevity of V Fabric Oil Seals

To fully leverage the benefits of V Fabric Oil Seals, proper maintenance practices must be implemented. Regular inspections and timely replacements can enhance their longevity and performance.

1. Regular Inspections

Routine inspections of seals should be conducted to identify any signs of wear or damage. Early detection of potential issues can prevent costly downtime and repairs.

2. Selecting the Right Seal

Choosing the appropriate seal for specific machinery and operating conditions is crucial. Consulting with manufacturers or seal experts can aid in selecting the right V Fabric Oil Seal to ensure compatibility and optimal performance.

Case Studies: Success Stories

Several forestry operations have reported significant improvements in performance and savings after switching to V Fabric Oil Seals. Here are a few notable examples:

1. Case Study 1: Large Scale Timber Harvesting

A large timber harvesting company replaced their traditional seals with V Fabric Oil Seals across their fleet. The result was a 30% reduction in maintenance costs due to fewer leaks and less downtime. This switch allowed the company to increase productivity significantly.

2. Case Study 2: Eco-friendly Forestry Practices

Another forestry company focused on eco-friendly practices found that implementing V Fabric Oil Seals not only enhanced their equipment's reliability but also aligned with their sustainability goals. The reduction in oil spills contributed to a cleaner operating environment.

Frequently Asked Questions

1. What are V Fabric Oil Seals made of?

V Fabric Oil Seals are typically made from a combination of high-quality fabric, such as polyester or nylon, and elastomers like nitrile or silicone, providing durability and flexibility for various applications.

2. How do V Fabric Oil Seals enhance performance?

These seals enhance performance by effectively preventing leaks, reducing contamination, and ensuring smooth operation, which ultimately leads to increased productivity and reduced maintenance costs.

3. Where are V Fabric Oil Seals commonly used?

They are commonly used in forestry equipment such as harvesters, skidders, and chippers, where reliable sealing is essential for optimal performance.

4. How often should V Fabric Oil Seals be replaced?

Replacement frequency depends on the operating conditions and the specific machinery. Regular inspections can help identify when a seal needs to be replaced.

5. Can V Fabric Oil Seals withstand extreme conditions?

Yes, V Fabric Oil Seals are designed to handle extreme temperatures, pressures, and contaminants, making them suitable for the harsh environments often encountered in forestry operations.

Conclusion

In conclusion, V Fabric Oil Seals are indispensable components in forestry equipment, enhancing performance and reliability while reducing maintenance costs. Their advanced design and material composition allow them to withstand the challenges of the forestry industry, making them a smart investment for any operation. As technology continues to evolve, the benefits of these seals will only increase, ensuring that forestry equipment remains efficient and environmentally friendly.

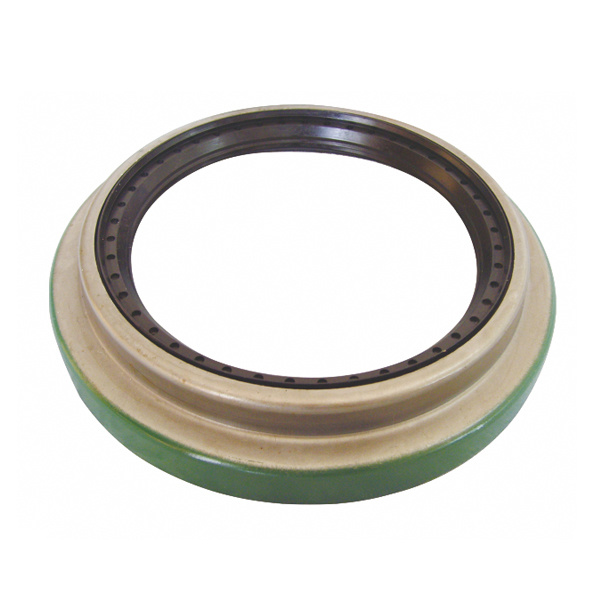

V Fabric Oil Seal for Forestry Equipment

RELEVANT INFORMATION

How is the quality of rubber seals controlled?

2023-05-05

Analysis of possible production problems and causes of silicone O-rings

2023-05-05

Transportation and assembly of oil seals

2023-05-05