Welcome To Know Our Products, We Can Offer You High Quality Products!

Understanding Cryogenic O-Rings: Essential Components for Automotive Sealing Solutions

2025-07-27

Cryogenic O-rings are specially designed sealing components that function effectively in environments with temperatures that can plummet to -268°C (-452°F). These O-rings are crucial in applications such as fuel systems, refrigeration, and various automotive components where extreme thermal conditions are a concern. Understanding the properties that make cryogenic O-rings suitable for these applic

Cryogenic O-rings are specially designed sealing components that function effectively in environments with temperatures that can plummet to -268°C (-452°F). These O-rings are crucial in applications such as fuel systems, refrigeration, and various automotive components where extreme thermal conditions are a concern. Understanding the properties that make cryogenic O-rings suitable for these applications is essential for professionals in the automotive and component manufacturing industries.

One of the key attributes of cryogenic O-rings is their material composition. Common materials used for these seals include fluorocarbon elastomers (FKM), perfluoroelastomers (FFKM), and silicone elastomers that are specifically formulated to withstand the rigors of low-temperature environments. The selection of the right material is vital, as it impacts the O-ring's flexibility, resilience, and ability to maintain a proper seal under cryogenic conditions.

When designing systems that require cryogenic O-rings, several factors must be considered. The seal’s compression set, temperature tolerance, and chemical compatibility with fluids or gases involved in the application are paramount. For instance, an O-ring that can withstand cryogenic temperatures must maintain its elasticity and sealing ability despite the inherent expansion and contraction of materials at these temperatures. Additionally, the O-ring must be resistant to potential chemical exposure, as many automotive applications involve various fluids that could compromise the integrity of standard sealing materials.

Another aspect of cryogenic O-rings that professionals should be aware of is the installation process. Proper installation is crucial to ensure the functionality of the seal. This includes ensuring that the sealing surfaces are clean and free from debris and that the O-ring is not twisted or pinched during the assembly of components. Consideration of the installation environment is also necessary, as rapid temperature changes can affect the performance of the O-ring.

Cryogenic O-rings are invaluable in helping to maintain the integrity of automotive components operating under extreme conditions. Their ability to provide reliable seals in such settings ensures that systems function efficiently and safely. For automotive professionals looking to enhance the reliability and performance of their sealing solutions, understanding the characteristics and applications of cryogenic O-rings can lead to more effective design choices and improved system performance.

In conclusion, cryogenic O-rings are specialized sealing components essential for various automotive applications, particularly those operating in low-temperature environments. By selecting the appropriate materials, considering installation practices, and understanding the performance characteristics of these O-rings, professionals can ensure optimal sealing solutions that enhance the reliability and safety of their systems.

One of the key attributes of cryogenic O-rings is their material composition. Common materials used for these seals include fluorocarbon elastomers (FKM), perfluoroelastomers (FFKM), and silicone elastomers that are specifically formulated to withstand the rigors of low-temperature environments. The selection of the right material is vital, as it impacts the O-ring's flexibility, resilience, and ability to maintain a proper seal under cryogenic conditions.

When designing systems that require cryogenic O-rings, several factors must be considered. The seal’s compression set, temperature tolerance, and chemical compatibility with fluids or gases involved in the application are paramount. For instance, an O-ring that can withstand cryogenic temperatures must maintain its elasticity and sealing ability despite the inherent expansion and contraction of materials at these temperatures. Additionally, the O-ring must be resistant to potential chemical exposure, as many automotive applications involve various fluids that could compromise the integrity of standard sealing materials.

Another aspect of cryogenic O-rings that professionals should be aware of is the installation process. Proper installation is crucial to ensure the functionality of the seal. This includes ensuring that the sealing surfaces are clean and free from debris and that the O-ring is not twisted or pinched during the assembly of components. Consideration of the installation environment is also necessary, as rapid temperature changes can affect the performance of the O-ring.

Cryogenic O-rings are invaluable in helping to maintain the integrity of automotive components operating under extreme conditions. Their ability to provide reliable seals in such settings ensures that systems function efficiently and safely. For automotive professionals looking to enhance the reliability and performance of their sealing solutions, understanding the characteristics and applications of cryogenic O-rings can lead to more effective design choices and improved system performance.

In conclusion, cryogenic O-rings are specialized sealing components essential for various automotive applications, particularly those operating in low-temperature environments. By selecting the appropriate materials, considering installation practices, and understanding the performance characteristics of these O-rings, professionals can ensure optimal sealing solutions that enhance the reliability and safety of their systems.

cryogenic o rings

RELEVANT INFORMATION

How is the quality of rubber seals controlled?

2023-05-05

The application range of silicone products is very wide, because it is both non-toxic and environmentally friendly, and does not depend on petroleum resources, so there are silicone products in all aspects of our lives, so under what circumstances will it affect the quality of silicone products? .

Analysis of possible production problems and causes of silicone O-rings

2023-05-05

Silicone O-shaped sealing ring is a kind of rubber ring with silicone as raw material and a circular cross-section. Because its cross-section is O-shaped, it is called silicone O-shaped sealing ring.

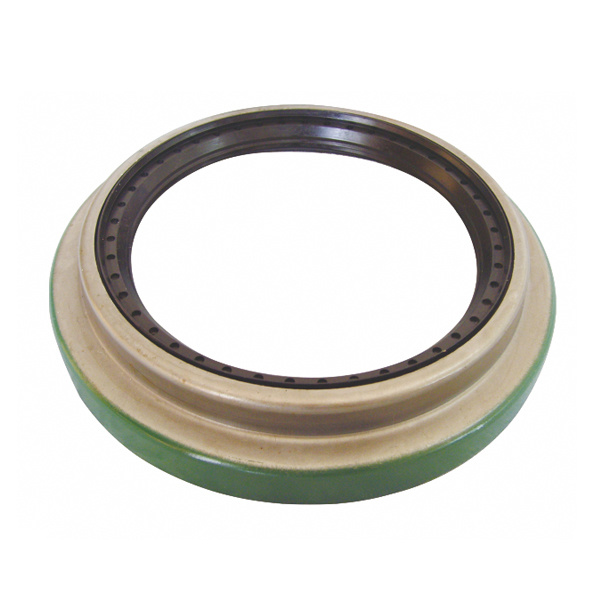

Transportation and assembly of oil seals

2023-05-05

Do not open the original packaging, pay attention to whether the packaging is damaged, and try to leave the oil seal in the original packaging before assembly.;