Welcome To Know Our Products, We Can Offer You High Quality Products!

Why High-Pressure PU Oil Seals Are Essential for Engine Performance

2025-10-08

Why High-Pressure PU Oil Seals Are Essential for Engine Performance

Table of Contents

1. Introduction to PU Oil Seals

2. Understanding the Importance of Engine Sealing

3. Advantages of High-Pressure PU Oil Seals

3.1 Enhanced Durability and Lifespan

3.2 Superior Resistance to Wear and Tear

3.3 Improved Performance and Efficiency

4. Applications of PU Oil Seals in Automotive Engines

Why High-Pressure PU Oil Seals Are Essential for Engine Performance

Table of Contents

1. Introduction to PU Oil Seals

2. Understanding the Importance of Engine Sealing

3. Advantages of High-Pressure PU Oil Seals

3.1 Enhanced Durability and Lifespan

3.2 Superior Resistance to Wear and Tear

3.3 Improved Performance and Efficiency

4. Applications of PU Oil Seals in Automotive Engines

5. Choosing the Right PU Oil Seal for Your Engine

5.1 Factors to Consider

5.2 Common Mistakes to Avoid

6. Maintenance Tips for PU Oil Seals

7. Frequently Asked Questions (FAQs)

8. Conclusion

1. Introduction to PU Oil Seals

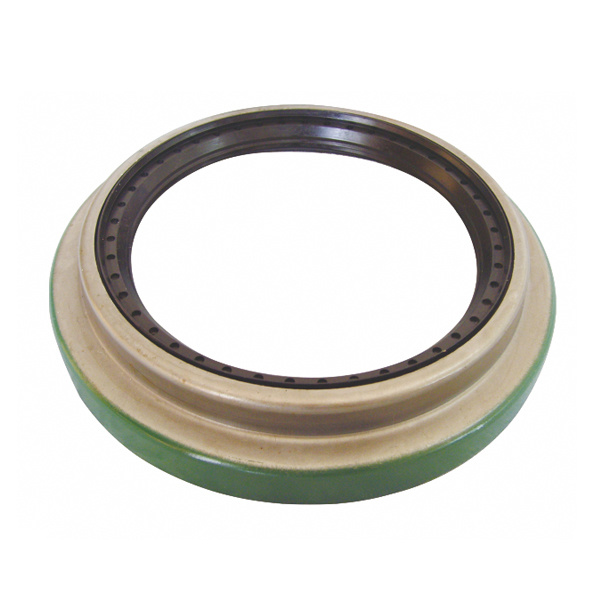

In the automotive industry, **PU oil seals** have emerged as a key component in ensuring optimal engine performance. Engine oil seals are designed to retain lubricants within the engine while preventing contaminants from entering. High-pressure PU oil seals, in particular, are engineered to withstand extreme conditions and pressures, making them essential for modern automotive engines.

2. Understanding the Importance of Engine Sealing

Effective sealing is crucial for any engine, as it directly impacts **engine efficiency** and longevity. A well-sealed engine minimizes the risk of oil leaks, which can lead to reduced lubrication, overheating, and ultimately engine failure. High-pressure PU oil seals play a pivotal role in achieving this seal, ensuring that the engine operates smoothly under varying conditions.

3. Advantages of High-Pressure PU Oil Seals

The benefits of utilizing high-pressure PU oil seals in engine systems are numerous, with each advantage contributing to enhanced vehicle performance.

3.1 Enhanced Durability and Lifespan

High-pressure PU oil seals are known for their **exceptional durability**. Manufactured from polyurethane, these seals possess a unique ability to resist degradation from oil and other automotive fluids, ensuring a longer service life. This durability translates into fewer replacements and lower maintenance costs.

3.2 Superior Resistance to Wear and Tear

PU oil seals exhibit remarkable resistance to wear and tear caused by friction and environmental factors. They can withstand high temperatures and pressures without losing their integrity, making them ideal for high-performance engines that operate under demanding conditions.

3.3 Improved Performance and Efficiency

With their excellent sealing capabilities, high-pressure PU oil seals significantly enhance engine performance. By preventing oil leaks, these seals help maintain optimal lubricant levels, ensuring that all engine components function smoothly. This results in improved fuel efficiency and overall engine performance.

4. Applications of PU Oil Seals in Automotive Engines

High-pressure PU oil seals are utilized in various applications within automotive engines. They are commonly found in crankshaft seals, camshaft seals, and transmission seals. Each application leverages the unique properties of PU materials to provide reliable sealing under high-pressure conditions.

5. Choosing the Right PU Oil Seal for Your Engine

Selecting the appropriate PU oil seal is critical for ensuring optimal engine performance.

5.1 Factors to Consider

When choosing a PU oil seal, consider the following factors:

- **Pressure Rating:** Ensure that the seal can withstand the pressure conditions of your engine.

- **Temperature Range:** Choose seals that can operate effectively within the temperature range of your engine.

- **Material Compatibility:** Verify that the seal material is compatible with the engine fluids to avoid chemical degradation.

5.2 Common Mistakes to Avoid

- **Overlooking Specifications:** Always consult the manufacturer’s specifications to ensure compatibility.

- **Ignoring Installation Guidelines:** Improper installation can lead to premature failure, so follow the guidelines carefully.

6. Maintenance Tips for PU Oil Seals

To extend the life of PU oil seals and maintain engine performance, implement the following maintenance tips:

- **Regular Inspections:** Periodically check for signs of wear, leaks, or damage.

- **Fluid Changes:** Regularly change engine oil and other fluids to minimize contamination.

- **Proper Installation:** Ensure seals are installed correctly to prevent premature failure.

7. Frequently Asked Questions (FAQs)

What are PU oil seals made from?

PU oil seals are primarily made from polyurethane, a material known for its flexibility, durability, and resistance to wear.

How do I know if my oil seal is failing?

Signs of a failing oil seal may include oil leaks, engine performance issues, and unusual noises coming from the engine.

Can I replace oil seals myself?

Yes, replacing oil seals can be a DIY task, but it requires a good understanding of engine mechanics and proper tools.

How often should I check my oil seals?

It’s advisable to check oil seals during regular maintenance, usually every 5,000 to 10,000 miles or as recommended by your vehicle’s manufacturer.

Are high-pressure PU oil seals worth the investment?

Absolutely. Their durability and performance benefits often outweigh the initial investment, leading to fewer replacements and lower long-term costs.

8. Conclusion

High-pressure PU oil seals are indispensable components in maintaining optimal engine performance. Their unique properties, including durability, resistance to wear, and superior sealing capabilities, make them an essential choice for modern automotive applications. Investing in high-quality PU oil seals not only enhances engine efficiency but also extends the lifespan of your vehicle, contributing to a smoother and more reliable driving experience. By understanding their importance and implementing proper maintenance practices, vehicle owners can ensure their engines perform at their best for years to come.

High-Pressure PU Oil Seals

RELEVANT INFORMATION

How is the quality of rubber seals controlled?

2023-05-05

The application range of silicone products is very wide, because it is both non-toxic and environmentally friendly, and does not depend on petroleum resources, so there are silicone products in all aspects of our lives, so under what circumstances will it affect the quality of silicone products? .

Analysis of possible production problems and causes of silicone O-rings

2023-05-05

Silicone O-shaped sealing ring is a kind of rubber ring with silicone as raw material and a circular cross-section. Because its cross-section is O-shaped, it is called silicone O-shaped sealing ring.

Transportation and assembly of oil seals

2023-05-05

Do not open the original packaging, pay attention to whether the packaging is damaged, and try to leave the oil seal in the original packaging before assembly.;