Welcome To Know Our Products, We Can Offer You High Quality Products!

Top Benefits of Using Agricultural Machine PU Oil Seals

2025-04-21

Top Benefits of Using Agricultural Machine PU Oil Seals

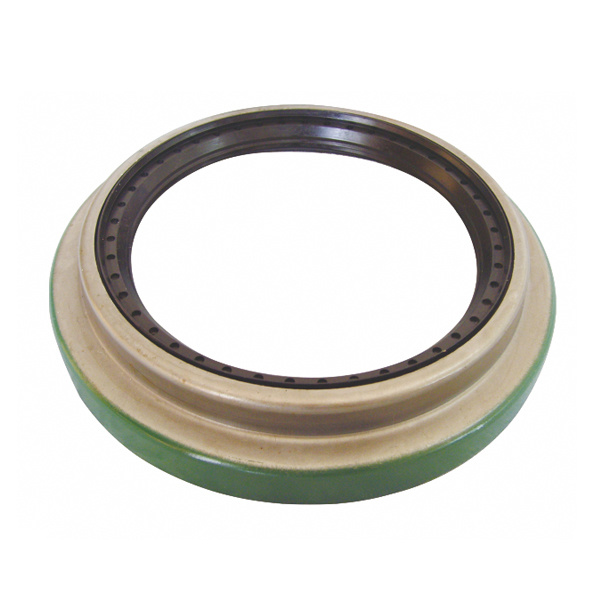

When it comes to the agricultural industry, the efficiency and reliability of machinery are paramount. Among the various components that contribute to the performance of agricultural machinery, **oil seals** play an essential role. In recent years, **Polyurethane (PU) oil seals** have gained significant attention for their numerous benefits. This article delves into the top advantages of using PU oil seals in agricultural machines, exploring their unique properties and applications.

1. Understanding PU Oil Seals

Before diving into the benefits, it's critical to understand what PU oil seals are and how they function. **Polyurethane** is a versatile material renowned for its durability and resistance to wear. **Oil seals**, also known as **shaft seals**, are designed to prevent the leakage of lubricants and contaminants from entering machinery. They are crucial for maintaining the integrity of the internal components of agricultural equipment.

1.1 Properties of Polyurethane

Polyurethane boasts several properties that make it an excellent choice for oil seals. These include:

- High tensile strength: PU oil seals can withstand high pressure and stress, ensuring longevity.

- Flexibility: The flexibility of PU allows for easy installation and adaptability to various shaft diameters.

- Resistance to abrasion: PU is highly resistant to wear and tear, making it suitable for harsh agricultural environments.

- Chemical resistance: PU oil seals resist various chemicals, including oils and fuels, ensuring optimal performance.

2. Enhanced Durability and Longevity

One of the most significant benefits of using PU oil seals in agricultural machinery is their enhanced durability. Unlike traditional rubber seals, PU seals resist degradation from environmental factors such as UV rays, moisture, and extreme temperatures. This durability translates to longer service life, reducing the frequency of replacements and maintenance.

2.1 Cost-Effectiveness Over Time

While the initial investment in PU oil seals may be higher than conventional seals, their longevity and reduced need for replacements make them a cost-effective solution in the long run. By minimizing downtime and maintenance costs, PU oil seals contribute to overall operational efficiency.

3. Improved Performance in Harsh Conditions

Agricultural machinery often operates in challenging environments, including exposure to dirt, dust, and extreme temperatures. PU oil seals excel in these conditions, providing a reliable barrier against contaminants. Their robust design ensures that they maintain a tight seal even when subjected to vibration and movement.

3.1 Optimal Lubrication Retention

Maintaining proper lubrication is essential for the performance of agricultural machinery. PU oil seals effectively retain lubricants, preventing leaks that can lead to increased friction and wear. This optimal lubrication retention not only enhances performance but also extends the life of critical components.

4. Versatility Across Various Applications

PU oil seals are incredibly versatile and can be used in a wide range of agricultural machinery, including:

- Tractors

- Harvesters

- Planters

- Sprayers

- Other industrial equipment

This versatility ensures that farmers can rely on PU oil seals for various applications, simplifying inventory management and reducing the need for different types of seals.

4.1 Compatibility with Different Machinery Types

PU oil seals are compatible with various machinery due to their customizable designs. Manufacturers can tailor the dimensions and specifications of PU seals to meet the requirements of different agricultural machines, enhancing their effectiveness and reliability.

5. Environmental Benefits

As the agricultural sector becomes more environmentally conscious, the use of PU oil seals aligns with sustainability efforts. PU materials are often more environmentally friendly than traditional rubber seals, contributing to a reduced carbon footprint.

5.1 Reduced Waste Through Longevity

Due to their extended lifespan, PU oil seals generate less waste compared to traditional seals that require frequent replacement. This reduction in waste is a step towards more sustainable farming practices.

6. Enhanced Sealing Performance

The sealing performance of PU oil seals is superior due to their design and material properties. They provide a tight, reliable seal that prevents the leakage of lubricants while blocking contaminants from entering the machinery.

6.1 Customizable Sealing Solutions

Manufacturers can create customized PU oil seals to address specific sealing challenges. This adaptability ensures that the seals effectively meet the unique demands of various agricultural applications, enhancing their sealing performance.

7. Installation and Maintenance Benefits

Installing PU oil seals is typically straightforward, offering several advantages in terms of maintenance and serviceability. Their flexibility and resilience make them easy to fit onto various shafts, reducing the time and effort required for installation.

7.1 Minimal Maintenance Needs

Once installed, PU oil seals require minimal maintenance due to their durability and resistance to wear. This low maintenance requirement allows farmers to focus on their operations rather than spending time on frequent seal replacements.

8. Frequently Asked Questions (FAQs)

8.1 What Are PU Oil Seals Made Of?

PU oil seals are made from polyurethane, a synthetic material known for its excellent durability, flexibility, and resistance to wear and chemicals.

8.2 How Do PU Oil Seals Compare to Rubber Seals?

PU oil seals typically offer better durability, resistance to environmental factors, and longer service life compared to traditional rubber seals.

8.3 Can PU Oil Seals Be Used in High-Temperature Applications?

Yes, PU oil seals are designed to withstand high-temperature applications, making them suitable for various agricultural machinery operating in extreme conditions.

8.4 How Do I Know If My Oil Seal Needs Replacement?

Signs of a failing oil seal include oil leaks, increased engine noise, and visible wear or damage to the seal. Regular inspection can help identify these issues early.

8.5 Are PU Oil Seals Environmentally Friendly?

Yes, PU oil seals are considered more environmentally friendly than traditional rubber seals, particularly due to their longevity and reduced waste generation.

Conclusion

In summary, the use of **Polyurethane (PU) oil seals** in agricultural machinery offers numerous benefits, including enhanced durability, improved performance, and versatility across various applications. Their ability to withstand harsh conditions while providing effective sealing makes them an invaluable component for optimizing equipment efficiency. Farmers and agricultural machinery operators can significantly enhance their operational effectiveness and sustainability by investing in PU oil seals. Adopting these innovative seals can lead to reduced maintenance costs, increased equipment longevity, and a commitment to environmentally friendly practices in the agricultural sector.

Agricultural Machine PU Oil Seals

RELEVANT INFORMATION

How is the quality of rubber seals controlled?

2023-05-05

Analysis of possible production problems and causes of silicone O-rings

2023-05-05

Transportation and assembly of oil seals

2023-05-05