Welcome To Know Our Products, We Can Offer You High Quality Products!

Understanding Agricultural Machine PU Oil Seals: Essential Components for Efficient Performance

2025-04-28

Agricultural machines play a crucial role in modern farming, aiding in various tasks such as planting, harvesting, and transportation of goods. To ensure their efficiency and longevity, every component must work harmoniously, and one of the unsung heroes in this machinery is the PU oil seal. PU, or polyurethane, oil seals are vital components that prevent the leakage of fluids and contaminants, th

Agricultural machines play a crucial role in modern farming, aiding in various tasks such as planting, harvesting, and transportation of goods. To ensure their efficiency and longevity, every component must work harmoniously, and one of the unsung heroes in this machinery is the PU oil seal. PU, or polyurethane, oil seals are vital components that prevent the leakage of fluids and contaminants, thereby maintaining the integrity and performance of engine systems.

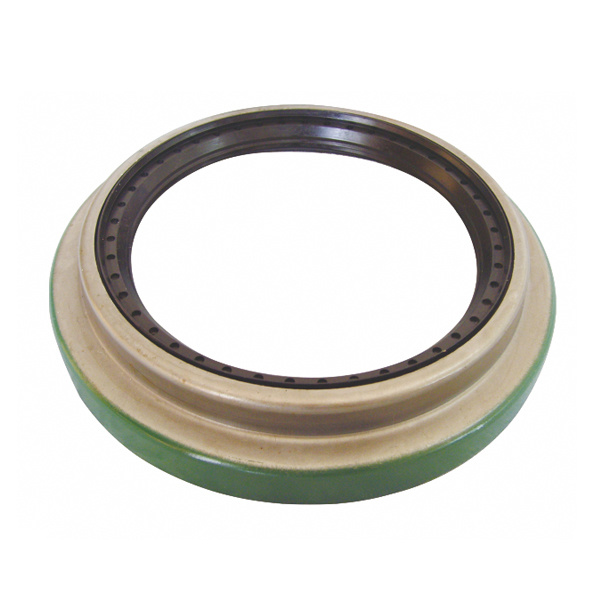

PU oil seals are designed to withstand harsh operating conditions, which are common in agricultural environments. These seals are made from a flexible and durable material that can handle a wide range of temperatures and pressures, making them ideal for use in engines that experience significant operational stress. Unlike traditional rubber seals, PU oil seals offer enhanced resistance to wear and tear, as well as superior sealing capabilities, which are essential for the longevity of agricultural equipment.

The primary function of PU oil seals is to create a barrier that prevents oil and other fluids from leaking out of the engine, while simultaneously keeping dirt, dust, and other contaminants from entering. This dual sealing capability is critical because fluid leaks can lead to reduced efficiency, increased maintenance costs, and potential engine failure. Additionally, contaminants can cause internal damage to engine components, leading to costly repairs and downtime.

In agricultural machinery, where downtime can significantly affect productivity, the reliability of PU oil seals becomes paramount. By ensuring that these seals are properly installed and maintained, operators can minimize the risk of leaks and extend the life of their equipment. Regular inspection and timely replacement of worn or damaged seals can prevent larger issues down the line, contributing to overall operational efficiency.

Furthermore, the selection of the right type of PU oil seal is essential. Various factors, such as the specific application, the type of fluids being sealed, and the operating environment, must be considered when choosing oil seals. Industrial standards and specifications can guide professionals in selecting the most suitable seals for their agricultural machinery, ensuring optimal performance and reliability.

In conclusion, PU oil seals are indispensable components in the maintenance of agricultural machines. Their ability to effectively seal engine systems not only prevents fluid loss but also protects against dirt and contaminants, thus enhancing the overall durability and efficiency of the equipment. For professionals in the automotive and agricultural sectors, understanding the importance of these seals is crucial for ensuring the smooth operation and longevity of machinery, ultimately supporting the productivity of modern farming practices.

PU oil seals are designed to withstand harsh operating conditions, which are common in agricultural environments. These seals are made from a flexible and durable material that can handle a wide range of temperatures and pressures, making them ideal for use in engines that experience significant operational stress. Unlike traditional rubber seals, PU oil seals offer enhanced resistance to wear and tear, as well as superior sealing capabilities, which are essential for the longevity of agricultural equipment.

The primary function of PU oil seals is to create a barrier that prevents oil and other fluids from leaking out of the engine, while simultaneously keeping dirt, dust, and other contaminants from entering. This dual sealing capability is critical because fluid leaks can lead to reduced efficiency, increased maintenance costs, and potential engine failure. Additionally, contaminants can cause internal damage to engine components, leading to costly repairs and downtime.

In agricultural machinery, where downtime can significantly affect productivity, the reliability of PU oil seals becomes paramount. By ensuring that these seals are properly installed and maintained, operators can minimize the risk of leaks and extend the life of their equipment. Regular inspection and timely replacement of worn or damaged seals can prevent larger issues down the line, contributing to overall operational efficiency.

Furthermore, the selection of the right type of PU oil seal is essential. Various factors, such as the specific application, the type of fluids being sealed, and the operating environment, must be considered when choosing oil seals. Industrial standards and specifications can guide professionals in selecting the most suitable seals for their agricultural machinery, ensuring optimal performance and reliability.

In conclusion, PU oil seals are indispensable components in the maintenance of agricultural machines. Their ability to effectively seal engine systems not only prevents fluid loss but also protects against dirt and contaminants, thus enhancing the overall durability and efficiency of the equipment. For professionals in the automotive and agricultural sectors, understanding the importance of these seals is crucial for ensuring the smooth operation and longevity of machinery, ultimately supporting the productivity of modern farming practices.

Agricultural Machine PU Oil Seals

RELEVANT INFORMATION

How is the quality of rubber seals controlled?

2023-05-05

The application range of silicone products is very wide, because it is both non-toxic and environmentally friendly, and does not depend on petroleum resources, so there are silicone products in all aspects of our lives, so under what circumstances will it affect the quality of silicone products? .

Analysis of possible production problems and causes of silicone O-rings

2023-05-05

Silicone O-shaped sealing ring is a kind of rubber ring with silicone as raw material and a circular cross-section. Because its cross-section is O-shaped, it is called silicone O-shaped sealing ring.

Transportation and assembly of oil seals

2023-05-05

Do not open the original packaging, pay attention to whether the packaging is damaged, and try to leave the oil seal in the original packaging before assembly.;