Welcome To Know Our Products, We Can Offer You High Quality Products!

Understanding Low Friction Valve Stem Seal: Enhancements for Industrial Sealing Solutions

2025-07-17

Low Friction Valve Stem Seals are critical components in various industrial applications, particularly in systems that require efficient sealing and reduced friction. These seals ensure the proper functioning of valves by controlling the flow of fluids and gases while minimizing wear and tear on mechanical components. By utilizing advanced materials and innovative designs, Low Friction Valve Stem

Low Friction Valve Stem Seals are critical components in various industrial applications, particularly in systems that require efficient sealing and reduced friction. These seals ensure the proper functioning of valves by controlling the flow of fluids and gases while minimizing wear and tear on mechanical components. By utilizing advanced materials and innovative designs, Low Friction Valve Stem Seals offer numerous benefits that can significantly enhance the performance of your equipment.

One of the primary advantages of Low Friction Valve Stem Seals is their ability to minimize friction between the valve stem and the seal itself. This reduction in friction leads to smoother operation and reduced energy consumption, which is essential for maintaining operational efficiency. As industries strive to lower their energy costs and improve sustainability, the use of low friction seals becomes increasingly important. Furthermore, the lower friction levels can extend the lifespan of the valve components, reducing the need for frequent replacements and maintenance.

The materials used in Low Friction Valve Stem Seals play a crucial role in their performance. Typically, these seals are made from high-quality polymers, elastomers, or composite materials that are engineered to withstand harsh operating conditions. Resistance to chemicals, high temperatures, and pressure variations are vital for ensuring the longevity and reliability of the seals. When selecting a material for Low Friction Valve Stem Seals, consider the specific requirements of your application, including the type of fluids being handled, temperature ranges, and potential exposure to corrosive substances.

Another important aspect to consider is the design of the valve stem seal. Low friction designs often feature unique geometries or surface treatments that further enhance sealing performance. For example, micro-textured surfaces can help reduce surface contact area, thus lowering friction while maintaining effective sealing. Additionally, some designs incorporate secondary sealing elements that provide an extra layer of protection against leaks, ensuring the integrity of the system.

Proper maintenance and installation practices are essential to maximizing the benefits of Low Friction Valve Stem Seals. Regular inspection of seals can help identify wear, damage, or contamination that may affect performance. Adhering to manufacturer guidelines during installation is equally important, as improper alignment or installation can lead to premature failure.

In summary, Low Friction Valve Stem Seals serve as a vital component in industrial sealing applications, providing enhanced efficiency, longevity, and reliability. By understanding the advantages, materials, and maintenance considerations associated with these seals, professionals can make informed decisions that optimize their operations and contribute to overall system performance. Whether you are looking to improve energy efficiency or extend the life of your valve systems, investing in Low Friction Valve Stem Seals can yield significant operational benefits.

One of the primary advantages of Low Friction Valve Stem Seals is their ability to minimize friction between the valve stem and the seal itself. This reduction in friction leads to smoother operation and reduced energy consumption, which is essential for maintaining operational efficiency. As industries strive to lower their energy costs and improve sustainability, the use of low friction seals becomes increasingly important. Furthermore, the lower friction levels can extend the lifespan of the valve components, reducing the need for frequent replacements and maintenance.

The materials used in Low Friction Valve Stem Seals play a crucial role in their performance. Typically, these seals are made from high-quality polymers, elastomers, or composite materials that are engineered to withstand harsh operating conditions. Resistance to chemicals, high temperatures, and pressure variations are vital for ensuring the longevity and reliability of the seals. When selecting a material for Low Friction Valve Stem Seals, consider the specific requirements of your application, including the type of fluids being handled, temperature ranges, and potential exposure to corrosive substances.

Another important aspect to consider is the design of the valve stem seal. Low friction designs often feature unique geometries or surface treatments that further enhance sealing performance. For example, micro-textured surfaces can help reduce surface contact area, thus lowering friction while maintaining effective sealing. Additionally, some designs incorporate secondary sealing elements that provide an extra layer of protection against leaks, ensuring the integrity of the system.

Proper maintenance and installation practices are essential to maximizing the benefits of Low Friction Valve Stem Seals. Regular inspection of seals can help identify wear, damage, or contamination that may affect performance. Adhering to manufacturer guidelines during installation is equally important, as improper alignment or installation can lead to premature failure.

In summary, Low Friction Valve Stem Seals serve as a vital component in industrial sealing applications, providing enhanced efficiency, longevity, and reliability. By understanding the advantages, materials, and maintenance considerations associated with these seals, professionals can make informed decisions that optimize their operations and contribute to overall system performance. Whether you are looking to improve energy efficiency or extend the life of your valve systems, investing in Low Friction Valve Stem Seals can yield significant operational benefits.

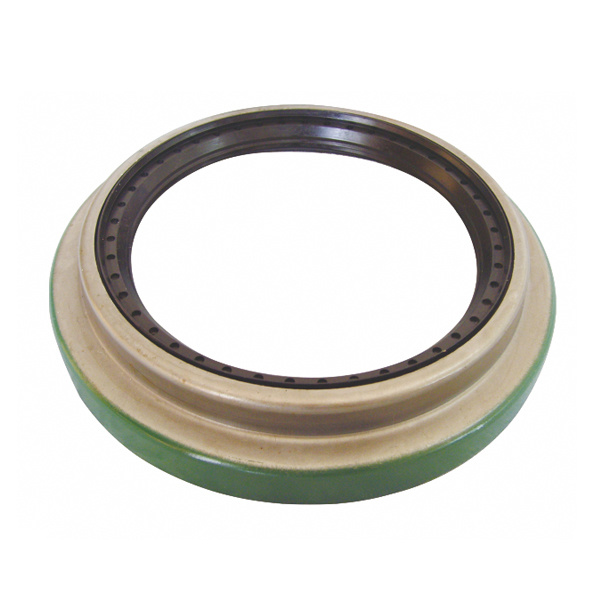

Low Friction Valve Stem Seal

RELEVANT INFORMATION

How is the quality of rubber seals controlled?

2023-05-05

The application range of silicone products is very wide, because it is both non-toxic and environmentally friendly, and does not depend on petroleum resources, so there are silicone products in all aspects of our lives, so under what circumstances will it affect the quality of silicone products? .

Analysis of possible production problems and causes of silicone O-rings

2023-05-05

Silicone O-shaped sealing ring is a kind of rubber ring with silicone as raw material and a circular cross-section. Because its cross-section is O-shaped, it is called silicone O-shaped sealing ring.

Transportation and assembly of oil seals

2023-05-05

Do not open the original packaging, pay attention to whether the packaging is damaged, and try to leave the oil seal in the original packaging before assembly.;