Welcome To Know Our Products, We Can Offer You High Quality Products!

Unlocking the Benefits of High-Pressure PU Oil Seals for Automotive Engines

2025-08-27

Unlocking the Benefits of High-Pressure PU Oil Seals for Automotive Engines

Table of Contents

Introduction to High-Pressure PU Oil Seals

What Are Oil Seals and Their Function?

High-Pressure PU Oil Seals: An Overview

Advantages of Using High-Pressure PU Oil Seals

Applications of High-Pressure PU Oil Seals in Automotive Engines

Installation Guidelines for PU Oil Seals

Maintenance Tips

Unlocking the Benefits of High-Pressure PU Oil Seals for Automotive Engines

Table of Contents

- Introduction to High-Pressure PU Oil Seals

- What Are Oil Seals and Their Function?

- High-Pressure PU Oil Seals: An Overview

- Advantages of Using High-Pressure PU Oil Seals

- Applications of High-Pressure PU Oil Seals in Automotive Engines

- Installation Guidelines for PU Oil Seals

- Maintenance Tips for Longevity

- Common Issues and Solutions

- Conclusion

- FAQs

Introduction to High-Pressure PU Oil Seals

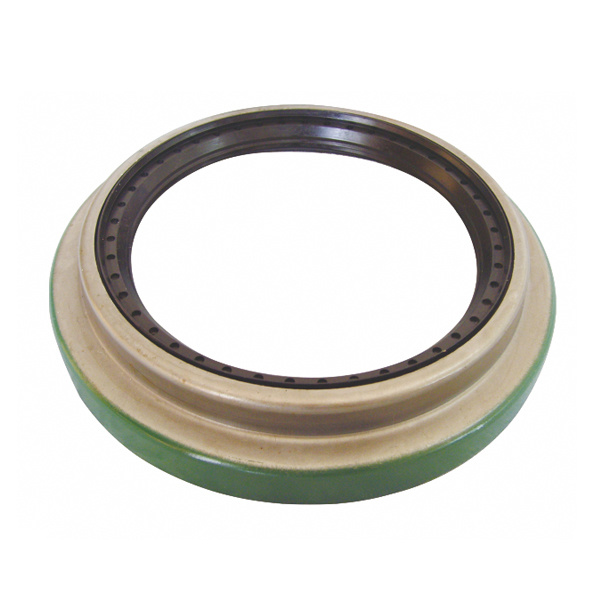

High-pressure polyurethane (PU) oil seals are essential components in modern automotive engines, designed to prevent the leakage of lubricants and fluids under extreme conditions. These seals are vital for maintaining optimal engine performance and longevity. In our exploration of high-pressure PU oil seals, we will delve into their unique properties, benefits, and practical applications.

What Are Oil Seals and Their Function?

Oil seals, also known as rotary seals or shaft seals, are mechanical components that prevent the escape of lubricants and the entry of contaminants into the engine. Typically composed of rubber or polymer materials, oil seals ensure that the engine operates smoothly and efficiently, protecting critical components from wear and tear.

How Oil Seals Work

The primary function of oil seals is to create a barrier around rotating shafts. By doing so, they minimize friction, reduce the risk of leaks, and prevent the ingress of dirt and debris. This functionality is crucial for maintaining the integrity of engine components, ensuring that the engine remains well-lubricated and operates within optimal temperature ranges.

High-Pressure PU Oil Seals: An Overview

High-pressure PU oil seals are specifically engineered to withstand elevated pressures and temperatures, making them suitable for demanding automotive applications. The use of polyurethane as a sealing material offers several advantages over traditional rubber seals, resulting in enhanced performance and durability.

Key Characteristics of PU Oil Seals

1. **Resistance to Chemical Degradation**: PU oil seals exhibit exceptional resistance to various chemicals, oils, and greases. This makes them ideal for use in environments where exposure to aggressive substances is common.

2. **High-Temperature Tolerance**: These seals maintain their integrity in high-temperature conditions, ensuring effective sealing even in extreme heat scenarios often encountered in automotive engines.

3. **Enhanced Flexibility and Elasticity**: The flexible nature of polyurethane allows for a better fit and seal, accommodating minor shaft misalignments while maintaining sealing effectiveness.

Advantages of Using High-Pressure PU Oil Seals

The adoption of high-pressure PU oil seals offers numerous benefits that can significantly improve engine performance and maintenance.

1. Improved Engine Efficiency

By effectively sealing lubricants within the engine, PU oil seals help maintain an optimal level of lubrication throughout the system. This leads to reduced friction, improved fuel efficiency, and overall enhanced engine performance.

2. Extended Component Lifespan

The robust design of PU oil seals minimizes wear and tear on engine components, extending their lifespan. This translates to fewer repairs and replacements over time, ultimately reducing maintenance costs.

3. Enhanced Leak Prevention

High-pressure PU oil seals are engineered to withstand higher pressures without compromising their sealing capabilities. This heightened leak prevention is essential for maintaining a clean engine environment and reducing the risk of engine failure.

4. Versatility in Applications

PU oil seals can be utilized in various automotive applications, from engine blocks to transmission systems. Their adaptability makes them a preferred choice for many automotive manufacturers.

Applications of High-Pressure PU Oil Seals in Automotive Engines

High-pressure PU oil seals are utilized in various automotive systems to ensure optimal performance and reliability. Key applications include:

1. Engine Crankshaft Sealing

PU oil seals effectively seal the crankshaft, preventing oil leaks while ensuring that the engine remains lubricated during operation.

2. Transmission Systems

In transmission systems, PU oil seals play a crucial role in maintaining fluid levels and preventing leaks, ensuring that the transmission operates smoothly and efficiently.

3. Differential Sealing

Differentials require reliable sealing solutions to prevent fluid loss. High-pressure PU oil seals are ideal for this application, providing excellent sealing performance under varying conditions.

4. Power Steering Systems

Power steering systems also benefit from the use of PU oil seals, which safeguard against fluid leaks and ensure the system operates effectively.

Installation Guidelines for PU Oil Seals

Proper installation of high-pressure PU oil seals is critical for achieving optimal performance. Adhering to the following guidelines can enhance the effectiveness of these seals:

1. Clean the Installation Area

Ensure that the surface where the seal will be installed is clean and free of debris. Contaminants can compromise the seal's integrity.

2. Lubricate the Seal

Applying a thin layer of lubricant to the seal can facilitate installation and ensure a snug fit. This reduces the risk of damage during the installation process.

3. Use Proper Tools

Utilize appropriate tools, such as seal drivers, to install the oil seal evenly. Avoid using excessive force, as this can lead to seal deformation.

4. Ensure Proper Alignment

Ensure that the seal is aligned correctly with the shaft. Misalignment can lead to premature seal failure and leaks.

Maintenance Tips for Longevity

To maximize the lifespan and performance of high-pressure PU oil seals, regular maintenance is essential. Here are some tips to consider:

1. Regular Inspections

Conduct routine inspections of the oil seals to check for signs of wear, damage, or leakage. Early detection of issues can prevent more significant problems down the line.

2. Monitor Fluid Levels

Keep an eye on fluid levels in the engine and transmission. Low fluid levels can create increased pressure on the seals, leading to potential failures.

3. Replace Worn Seals Promptly

If any signs of wear or damage are detected, replace the oil seals promptly to prevent leaks and maintain engine integrity.

Common Issues and Solutions

Despite their robust design, high-pressure PU oil seals may encounter certain issues. Understanding these problems can help in addressing them effectively.

1. Leaks

**Problem**: Leaks can occur due to improper installation or wear.

**Solution**: Ensure that seals are installed correctly and inspect them regularly. Replace any worn seals immediately.

2. Degradation from Chemicals

**Problem**: Exposure to aggressive chemicals can degrade the seal material.

**Solution**: Use seals specifically designed for the intended application, ensuring they can withstand chemical exposure.

3. Misalignment

**Problem**: Misalignment can lead to uneven wear and seal failure.

**Solution**: Ensure proper alignment during installation and regularly check for any alignment issues in the system.

Conclusion

High-pressure PU oil seals represent a significant advancement in automotive sealing technology, offering numerous benefits such as improved engine efficiency, extended lifespan of components, and superior leak prevention. Their versatility makes them suitable for various applications within automotive engines, ensuring optimal performance and reliability. By understanding the characteristics and proper maintenance of these seals, automotive enthusiasts and professionals can significantly enhance the longevity and efficiency of their vehicles. Adopting high-pressure PU oil seals is a proactive measure in maintaining engine health and performance, paving the way for a future of advanced automotive technology.

FAQs

1. What are the main advantages of using PU oil seals over rubber seals?

PU oil seals offer superior resistance to chemicals and high temperatures, as well as enhanced flexibility, making them more durable than traditional rubber seals.

2. Can high-pressure PU oil seals be used in all automotive applications?

While PU oil seals are versatile, it is essential to choose the right seal for specific applications to ensure optimal performance.

3. How often should oil seals be inspected?

Regular inspections should be conducted at least once a year, or more frequently in high-performance vehicles or extreme conditions.

4. What are the signs that an oil seal needs to be replaced?

Common signs include visible leaks, decreased fluid levels, and unusual noises from the engine or transmission.

5. Are high-pressure PU oil seals environmentally friendly?

PU materials can be more environmentally friendly than traditional rubber, but it’s essential to consider the specific manufacturing processes and disposal methods involved.

High-Pressure PU Oil Seals

RELEVANT INFORMATION

How is the quality of rubber seals controlled?

2023-05-05

The application range of silicone products is very wide, because it is both non-toxic and environmentally friendly, and does not depend on petroleum resources, so there are silicone products in all aspects of our lives, so under what circumstances will it affect the quality of silicone products? .

Analysis of possible production problems and causes of silicone O-rings

2023-05-05

Silicone O-shaped sealing ring is a kind of rubber ring with silicone as raw material and a circular cross-section. Because its cross-section is O-shaped, it is called silicone O-shaped sealing ring.

Transportation and assembly of oil seals

2023-05-05

Do not open the original packaging, pay attention to whether the packaging is damaged, and try to leave the oil seal in the original packaging before assembly.;