Welcome To Know Our Products, We Can Offer You High Quality Products!

Essential Guide to Engine Repair Kits for Heavy Machinery

2025-09-03

Engine Repair Kits for Heavy Machinery play a crucial role in the maintenance and repair of large equipment utilized in construction, mining, and industrial applications. These kits are specially designed to provide all the necessary components and tools to address a range of engine issues, ensuring that your heavy machinery operates efficiently and reliably.

One of the primary benefits of an Engi

Engine Repair Kits for Heavy Machinery play a crucial role in the maintenance and repair of large equipment utilized in construction, mining, and industrial applications. These kits are specially designed to provide all the necessary components and tools to address a range of engine issues, ensuring that your heavy machinery operates efficiently and reliably.

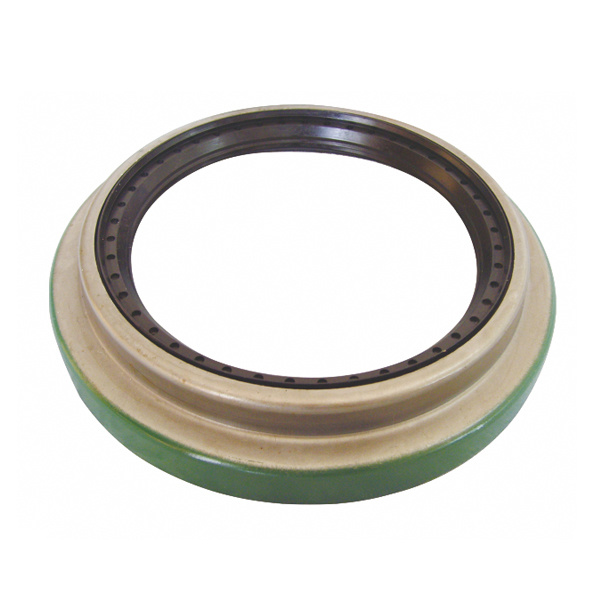

One of the primary benefits of an Engine Repair Kit is the convenience it offers. These kits typically include essential parts such as gaskets, seals, bearings, and other components needed for a comprehensive engine rebuild or repair. By having all these components in one package, technicians can save valuable time that would otherwise be spent sourcing individual parts. This is particularly important for heavy machinery, where downtime can lead to significant productivity losses.

Furthermore, Engine Repair Kits are often tailored to specific models of machinery, ensuring compatibility and optimal performance. This means that when using a repair kit, you can trust that each component is designed to work together seamlessly. For instance, if you are working on a specific brand of excavator or bulldozer, a dedicated engine repair kit will contain parts that meet the manufacturer's specifications.

Regular maintenance using these kits can help prevent more severe and costly repairs down the line. Heavy machinery operates under extreme conditions, and the engine is one of the most critical components subject to wear and tear. By utilizing an Engine Repair Kit, operators can address minor issues before they escalate, ensuring that the machinery remains in top condition. Regular checks and timely repairs not only enhance the machinery's performance but also extend its lifespan, providing long-term value to operators and businesses.

In addition to the technical components, many Engine Repair Kits also come with detailed instructions or guidelines on how to perform the repairs. This can be particularly helpful for those who may not be professional mechanics but are nonetheless tasked with maintaining heavy machinery. Clear, step-by-step instructions can empower operators to complete repairs with confidence, ensuring that they can keep their machines running smoothly.

In conclusion, Engine Repair Kits for Heavy Machinery are invaluable resources for maintaining and repairing engines effectively. They provide convenience, compatibility, and comprehensive solutions for technicians and operators alike. Investing in a quality engine repair kit not only enhances the reliability of heavy machinery but also contributes to the overall efficiency of operations, making it a smart choice for any business involved in heavy equipment usage.

One of the primary benefits of an Engine Repair Kit is the convenience it offers. These kits typically include essential parts such as gaskets, seals, bearings, and other components needed for a comprehensive engine rebuild or repair. By having all these components in one package, technicians can save valuable time that would otherwise be spent sourcing individual parts. This is particularly important for heavy machinery, where downtime can lead to significant productivity losses.

Furthermore, Engine Repair Kits are often tailored to specific models of machinery, ensuring compatibility and optimal performance. This means that when using a repair kit, you can trust that each component is designed to work together seamlessly. For instance, if you are working on a specific brand of excavator or bulldozer, a dedicated engine repair kit will contain parts that meet the manufacturer's specifications.

Regular maintenance using these kits can help prevent more severe and costly repairs down the line. Heavy machinery operates under extreme conditions, and the engine is one of the most critical components subject to wear and tear. By utilizing an Engine Repair Kit, operators can address minor issues before they escalate, ensuring that the machinery remains in top condition. Regular checks and timely repairs not only enhance the machinery's performance but also extend its lifespan, providing long-term value to operators and businesses.

In addition to the technical components, many Engine Repair Kits also come with detailed instructions or guidelines on how to perform the repairs. This can be particularly helpful for those who may not be professional mechanics but are nonetheless tasked with maintaining heavy machinery. Clear, step-by-step instructions can empower operators to complete repairs with confidence, ensuring that they can keep their machines running smoothly.

In conclusion, Engine Repair Kits for Heavy Machinery are invaluable resources for maintaining and repairing engines effectively. They provide convenience, compatibility, and comprehensive solutions for technicians and operators alike. Investing in a quality engine repair kit not only enhances the reliability of heavy machinery but also contributes to the overall efficiency of operations, making it a smart choice for any business involved in heavy equipment usage.

Engine Repair Kit for Heavy Machinery

RELEVANT INFORMATION

How is the quality of rubber seals controlled?

2023-05-05

The application range of silicone products is very wide, because it is both non-toxic and environmentally friendly, and does not depend on petroleum resources, so there are silicone products in all aspects of our lives, so under what circumstances will it affect the quality of silicone products? .

Analysis of possible production problems and causes of silicone O-rings

2023-05-05

Silicone O-shaped sealing ring is a kind of rubber ring with silicone as raw material and a circular cross-section. Because its cross-section is O-shaped, it is called silicone O-shaped sealing ring.

Transportation and assembly of oil seals

2023-05-05

Do not open the original packaging, pay attention to whether the packaging is damaged, and try to leave the oil seal in the original packaging before assembly.;