Welcome To Know Our Products, We Can Offer You High Quality Products!

Unlocking Efficiency: The Essential Heavy Equipment Repair Kits

2025-09-10

Unlocking Efficiency: The Essential Heavy Equipment Repair Kits

Introduction to Heavy Equipment Repair Kits

In the world of construction and heavy machinery, downtime can lead to significant losses in productivity and revenue. To combat these challenges, **heavy equipment repair kits** are essential tools that empower technicians and operators to perform maintenance and repairs efficiently. This

Unlocking Efficiency: The Essential Heavy Equipment Repair Kits

Introduction to Heavy Equipment Repair Kits

In the world of construction and heavy machinery, downtime can lead to significant losses in productivity and revenue. To combat these challenges, **heavy equipment repair kits** are essential tools that empower technicians and operators to perform maintenance and repairs efficiently. This article delves deep into the importance of these kits, their components, and how they play a pivotal role in ensuring that heavy equipment operates at optimal levels.

The Importance of Heavy Equipment Maintenance

Heavy equipment, from excavators to bulldozers, is subjected to harsh conditions, making regular maintenance vital. Here’s why maintaining your machinery through the right repair kits is critical:

Maximizing Uptime

Downtime translates to lost income, which is why having readily available repair kits can drastically reduce the time equipment spends out of commission. Quick fixes can prevent minor issues from becoming major problems, which can save substantial amounts of money and time.

Ensuring Safety

Well-maintained equipment leads to safer work environments. Regular maintenance using the right tools ensures that machinery operates safely, minimizing the risk of accidents that could cause injury to workers.

Extending Equipment Lifespan

Investing in quality repair kits not only allows for immediate repairs but also helps in the long-term maintenance of equipment. Consistent use of effective tools can prolong the lifespan of your heavy machinery, providing a better return on investment.

Components of Heavy Equipment Repair Kits

Understanding what goes into a heavy equipment repair kit is crucial for selecting the right one for your needs. Here are the primary components typically found in these kits:

1. Basic Hand Tools

Most repair kits contain essential hand tools such as wrenches, screwdrivers, and pliers. These are crucial for performing a wide range of repairs and adjustments.

2. Diagnostic Tools

High-quality repair kits often include diagnostic tools that can help identify issues within the machinery. These tools can range from multimeters to specific electronic diagnostic equipment.

3. Replacement Parts

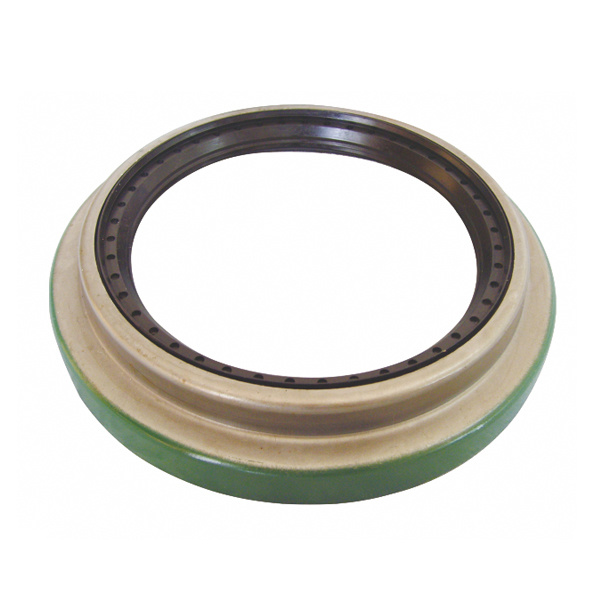

Having a stash of commonly needed replacement parts – such as filters, belts, and seals – is vital. These components can be quickly swapped out to keep machinery running smoothly.

4. Lubricants and Sealants

Proper lubrication is essential for the smooth operation of heavy equipment. Repair kits often include various lubricants and sealants to prevent wear and tear.

5. Instruction Manuals

Many repair kits come with manuals that provide detailed instructions for common repairs and maintenance tasks, making them more user-friendly.

Types of Heavy Equipment Repair Kits

Different types of heavy equipment require specialized repair kits to address their unique maintenance needs. Here’s a breakdown of the various types:

1. Excavator Repair Kits

Excavators are heavily utilized in construction. Their repair kits are designed to address hydraulic systems, tracks, and engine components that require specific maintenance tools.

2. Bulldozer Repair Kits

Bulldozers face unique challenges, including blade wear and hydraulic system issues. A well-rounded repair kit for bulldozers will focus on these specific aspects.

3. Loader Repair Kits

Loaders are essential for material handling. Their kits often focus on the hydraulic components, wheels, and engine maintenance.

4. Forklift Repair Kits

Forklifts play a critical role in warehousing and logistics. Their repair kits often include tools for battery maintenance, tire replacements, and engine diagnostics.

How to Choose the Right Heavy Equipment Repair Kit

Selecting the right repair kit can be overwhelming, given the vast array of options. Here’s how to make an informed choice:

1. Assess Your Needs

Consider the type of equipment you own, and identify the most common issues you encounter. This insight will guide you in selecting a kit that meets your specific requirements.

2. Quality Over Quantity

Opt for kits that offer high-quality tools and components. A kit with few but durable tools is often better than one stocked with inferior, disposable items.

3. Look for Comprehensive Solutions

Choose kits that offer a wide range of tools and parts. A more comprehensive kit can save you time and money in the long run.

4. Read Reviews

Before purchasing, read customer reviews and ratings. This feedback can provide valuable insights into the kit's effectiveness and durability.

Maintenance Tips for Heavy Equipment

Using a repair kit effectively requires knowledge of best practices for maintaining heavy equipment. Here are some useful tips:

1. Develop a Regular Maintenance Schedule

Establishing a routine maintenance schedule ensures that equipment is serviced regularly, reducing the likelihood of unexpected breakdowns.

2. Train Your Staff

Ensure your team is trained in proper maintenance techniques and tools usage. Knowledgeable staff can help detect issues early and utilize the repair kits effectively.

3. Keep Spare Parts on Hand

Having a selection of spare parts readily available can greatly reduce downtime. It’s wise to stock essential items based on the equipment you use most frequently.

4. Document Repairs and Maintenance

Maintaining records of repairs and maintenance activities can help track performance and identify recurring issues that may need addressing.

The Financial Impact of Using Repair Kits

Investing in heavy equipment repair kits delivers significant financial benefits:

1. Cost Savings

By being able to perform repairs in-house, businesses can avoid expensive labor costs associated with hiring external technicians.

2. Reduced Downtime Costs

Minimizing equipment downtime directly impacts productivity and revenue. Repair kits allow for swift fixes, keeping operations running smoothly.

3. Better Equipment Resale Value

Well-maintained equipment fetches a higher resale value. Regular use of repair kits ensures that machinery remains in good working condition, appealing to potential buyers.

FAQs about Heavy Equipment Repair Kits

1. What are heavy equipment repair kits used for?

Heavy equipment repair kits are used for maintaining and repairing various types of machinery, allowing operators to perform essential repairs and reduce downtime.

2. What should I look for in a heavy equipment repair kit?

When selecting a kit, consider the type of equipment, the quality of tools, comprehensiveness, and customer reviews to make an informed choice.

3. Can I use these repair kits on multiple types of equipment?

Some kits are designed for specific equipment, while others can be versatile. Always check compatibility before using a repair kit on different machines.

4. How often should I perform maintenance on my heavy equipment?

Maintenance frequency can vary based on usage, but a regular schedule—typically monthly or quarterly—is recommended to prevent issues.

5. Are heavy equipment repair kits cost-effective?

Yes, investing in repair kits can lead to significant savings by reducing the need for professional service and minimizing downtime.

Conclusion

Heavy equipment repair kits are essential tools that unlock efficiency and ensure the smooth operation of machinery in various industries. By understanding their components, choosing the right kit, and implementing effective maintenance practices, businesses can improve productivity, enhance safety, and extend the lifespan of their equipment. Investing in quality repair kits is not just a smart financial decision; it's a proactive approach to maintaining operational excellence in a demanding field.

Heavy Equipment Repair Kits

RELEVANT INFORMATION

How is the quality of rubber seals controlled?

2023-05-05

The application range of silicone products is very wide, because it is both non-toxic and environmentally friendly, and does not depend on petroleum resources, so there are silicone products in all aspects of our lives, so under what circumstances will it affect the quality of silicone products? .

Analysis of possible production problems and causes of silicone O-rings

2023-05-05

Silicone O-shaped sealing ring is a kind of rubber ring with silicone as raw material and a circular cross-section. Because its cross-section is O-shaped, it is called silicone O-shaped sealing ring.

Transportation and assembly of oil seals

2023-05-05

Do not open the original packaging, pay attention to whether the packaging is damaged, and try to leave the oil seal in the original packaging before assembly.;