Welcome To Know Our Products, We Can Offer You High Quality Products!

Understanding Valve Stem Seals: Essential Components for Engine Performance

2025-09-17

Valve stem seals are vital components in an internal combustion engine, serving as a barrier between the engine's combustion chamber and the valve guides. They are designed to prevent oil from entering the combustion chamber while allowing the valve to operate smoothly. By doing so, valve stem seals help maintain engine performance, reduce emissions, and prevent oil consumption.

The primary functi

Valve stem seals are vital components in an internal combustion engine, serving as a barrier between the engine's combustion chamber and the valve guides. They are designed to prevent oil from entering the combustion chamber while allowing the valve to operate smoothly. By doing so, valve stem seals help maintain engine performance, reduce emissions, and prevent oil consumption.

The primary function of valve stem seals is to regulate the lubrication of the valve stems. When the engine operates, the valve moves up and down, and the seal ensures that a small amount of oil lubricates the valve stem without allowing excessive oil to leak into the combustion chamber. If the seals are functioning correctly, they help maintain engine efficiency and minimize oil burning, which can lead to increased emissions and reduced engine power.

There are different types of valve stem seals, including umbrella seals and positive seals. Umbrella seals, often made from rubber, cover the valve stem and allow for some oil flow while minimizing leakage. Positive seals, on the other hand, create a tighter fit around the valve stem and are typically used in high-performance engines to reduce oil consumption even further. Understanding the differences between these types can guide vehicle owners and mechanics in selecting the right seal for their specific engine requirements.

Over time, valve stem seals can wear out due to heat, pressure, and the chemical composition of engine oils. When this occurs, you may notice symptoms such as increased oil consumption, bluish smoke from the exhaust, or a rough idle. Addressing these issues promptly is crucial, as neglecting worn seals can lead to more severe engine problems, including valve guide wear and overall engine damage.

Regular maintenance is key to ensuring the longevity of valve stem seals. It's advisable to follow the manufacturer's guidelines for oil changes and use high-quality engine oil that is compatible with the engine's specifications. Additionally, periodic inspections can help identify signs of wear before they escalate into significant issues.

When it comes to automotive performance, the small components like valve stem seals play a significant role in overall efficiency and engine health. By ensuring these seals are in good condition, vehicle owners can enhance their engine's performance, reduce emissions, and prolong the life of their automobile. Understanding the importance of valve stem seals will empower you to make informed decisions regarding your vehicle's maintenance and care.

The primary function of valve stem seals is to regulate the lubrication of the valve stems. When the engine operates, the valve moves up and down, and the seal ensures that a small amount of oil lubricates the valve stem without allowing excessive oil to leak into the combustion chamber. If the seals are functioning correctly, they help maintain engine efficiency and minimize oil burning, which can lead to increased emissions and reduced engine power.

There are different types of valve stem seals, including umbrella seals and positive seals. Umbrella seals, often made from rubber, cover the valve stem and allow for some oil flow while minimizing leakage. Positive seals, on the other hand, create a tighter fit around the valve stem and are typically used in high-performance engines to reduce oil consumption even further. Understanding the differences between these types can guide vehicle owners and mechanics in selecting the right seal for their specific engine requirements.

Over time, valve stem seals can wear out due to heat, pressure, and the chemical composition of engine oils. When this occurs, you may notice symptoms such as increased oil consumption, bluish smoke from the exhaust, or a rough idle. Addressing these issues promptly is crucial, as neglecting worn seals can lead to more severe engine problems, including valve guide wear and overall engine damage.

Regular maintenance is key to ensuring the longevity of valve stem seals. It's advisable to follow the manufacturer's guidelines for oil changes and use high-quality engine oil that is compatible with the engine's specifications. Additionally, periodic inspections can help identify signs of wear before they escalate into significant issues.

When it comes to automotive performance, the small components like valve stem seals play a significant role in overall efficiency and engine health. By ensuring these seals are in good condition, vehicle owners can enhance their engine's performance, reduce emissions, and prolong the life of their automobile. Understanding the importance of valve stem seals will empower you to make informed decisions regarding your vehicle's maintenance and care.

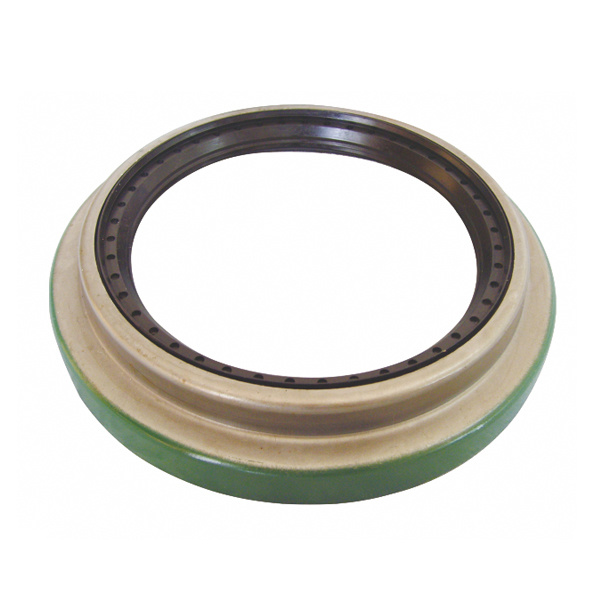

Valve Stem Seal

RELEVANT INFORMATION

How is the quality of rubber seals controlled?

2023-05-05

The application range of silicone products is very wide, because it is both non-toxic and environmentally friendly, and does not depend on petroleum resources, so there are silicone products in all aspects of our lives, so under what circumstances will it affect the quality of silicone products? .

Analysis of possible production problems and causes of silicone O-rings

2023-05-05

Silicone O-shaped sealing ring is a kind of rubber ring with silicone as raw material and a circular cross-section. Because its cross-section is O-shaped, it is called silicone O-shaped sealing ring.

Transportation and assembly of oil seals

2023-05-05

Do not open the original packaging, pay attention to whether the packaging is damaged, and try to leave the oil seal in the original packaging before assembly.;