Welcome To Know Our Products, We Can Offer You High Quality Products!

Essential Insights on Engine Repair Kits for Heavy Machinery

2025-10-15

When it comes to maintaining heavy machinery, understanding the intricacies of engine repair is crucial. An Engine Repair Kit for Heavy Machinery serves as an essential resource for professionals tasked with equipment maintenance and repairs. These kits typically include various components designed to address common engine issues, ensuring machinery operates efficiently and reliably.

Key component

When it comes to maintaining heavy machinery, understanding the intricacies of engine repair is crucial. An Engine Repair Kit for Heavy Machinery serves as an essential resource for professionals tasked with equipment maintenance and repairs. These kits typically include various components designed to address common engine issues, ensuring machinery operates efficiently and reliably.

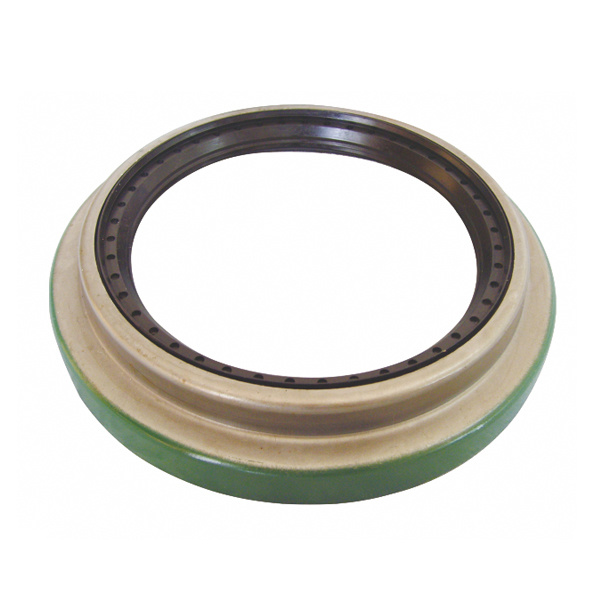

Key components of an Engine Repair Kit often encompass gaskets, seals, pistons, rings, and bearings, among other parts. Each of these components plays a vital role in the overall functionality of the engine. For instance, gaskets create a seal between engine parts to prevent leakage of fluids, while seals protect against dirt and contaminants entering critical engine areas.

The advantages of using an Engine Repair Kit are manifold. Firstly, it streamlines the repair process by providing all necessary components in one package, saving time and effort in sourcing individual parts. Secondly, these kits are designed to meet specific engine requirements, ensuring compatibility and optimal performance. This can significantly reduce the risk of future breakdowns, which is particularly important for heavy machinery that operates under demanding conditions.

Additionally, using a comprehensive repair kit can lead to cost savings over time. Regular maintenance and timely repairs prevent larger, more costly issues from developing. By addressing engine problems early, operators can extend the lifespan of their machinery, which is a crucial consideration in industries that rely heavily on heavy equipment.

For professionals using these kits, there are best practices to follow to ensure successful repairs. Firstly, always refer to the machinery's service manual for guidance on the appropriate kit and repair procedures. This can help avoid common pitfalls and ensure that repairs are conducted correctly. Secondly, cleanliness is paramount. When working on an engine, it’s essential to keep parts free from dirt and debris to prevent contamination that could lead to further problems.

Lastly, after completing repairs, it's advisable to conduct thorough testing of the machinery. This involves running the engine under normal operating conditions to confirm that all components are functioning correctly and that there are no leaks or unusual noises.

In summary, an Engine Repair Kit for Heavy Machinery is an indispensable tool for maintenance professionals. By equipping yourself with the right knowledge and components, you can ensure that your machinery remains in peak condition, ultimately enhancing productivity and reducing downtime. Emphasizing regular maintenance and adhering to best practices will further safeguard your investments in heavy equipment.

Key components of an Engine Repair Kit often encompass gaskets, seals, pistons, rings, and bearings, among other parts. Each of these components plays a vital role in the overall functionality of the engine. For instance, gaskets create a seal between engine parts to prevent leakage of fluids, while seals protect against dirt and contaminants entering critical engine areas.

The advantages of using an Engine Repair Kit are manifold. Firstly, it streamlines the repair process by providing all necessary components in one package, saving time and effort in sourcing individual parts. Secondly, these kits are designed to meet specific engine requirements, ensuring compatibility and optimal performance. This can significantly reduce the risk of future breakdowns, which is particularly important for heavy machinery that operates under demanding conditions.

Additionally, using a comprehensive repair kit can lead to cost savings over time. Regular maintenance and timely repairs prevent larger, more costly issues from developing. By addressing engine problems early, operators can extend the lifespan of their machinery, which is a crucial consideration in industries that rely heavily on heavy equipment.

For professionals using these kits, there are best practices to follow to ensure successful repairs. Firstly, always refer to the machinery's service manual for guidance on the appropriate kit and repair procedures. This can help avoid common pitfalls and ensure that repairs are conducted correctly. Secondly, cleanliness is paramount. When working on an engine, it’s essential to keep parts free from dirt and debris to prevent contamination that could lead to further problems.

Lastly, after completing repairs, it's advisable to conduct thorough testing of the machinery. This involves running the engine under normal operating conditions to confirm that all components are functioning correctly and that there are no leaks or unusual noises.

In summary, an Engine Repair Kit for Heavy Machinery is an indispensable tool for maintenance professionals. By equipping yourself with the right knowledge and components, you can ensure that your machinery remains in peak condition, ultimately enhancing productivity and reducing downtime. Emphasizing regular maintenance and adhering to best practices will further safeguard your investments in heavy equipment.

Engine Repair Kit for Heavy Machinery

RELEVANT INFORMATION

How is the quality of rubber seals controlled?

2023-05-05

The application range of silicone products is very wide, because it is both non-toxic and environmentally friendly, and does not depend on petroleum resources, so there are silicone products in all aspects of our lives, so under what circumstances will it affect the quality of silicone products? .

Analysis of possible production problems and causes of silicone O-rings

2023-05-05

Silicone O-shaped sealing ring is a kind of rubber ring with silicone as raw material and a circular cross-section. Because its cross-section is O-shaped, it is called silicone O-shaped sealing ring.

Transportation and assembly of oil seals

2023-05-05

Do not open the original packaging, pay attention to whether the packaging is damaged, and try to leave the oil seal in the original packaging before assembly.;