Welcome To Know Our Products, We Can Offer You High Quality Products!

Essential Insights on Engine Repair Kits for Heavy Machinery

2025-11-26

When it comes to maintaining heavy machinery, one critical aspect is ensuring that the engine operates at its peak performance. An Engine Repair Kit specifically designed for heavy machinery can be a game-changer for maintenance professionals. These kits typically include a variety of components needed to perform essential repairs and maintenance tasks, ensuring that the machinery remains operatio

When it comes to maintaining heavy machinery, one critical aspect is ensuring that the engine operates at its peak performance. An Engine Repair Kit specifically designed for heavy machinery can be a game-changer for maintenance professionals. These kits typically include a variety of components needed to perform essential repairs and maintenance tasks, ensuring that the machinery remains operational and efficient.

One of the primary components of an Engine Repair Kit for Heavy Machinery is gaskets. Gaskets play a crucial role in preventing leaks between engine components, thereby ensuring the proper functioning of the engine. Over time, gaskets can wear out due to high temperatures and pressure, leading to leaks that can cause significant damage if not addressed promptly. A comprehensive repair kit will often contain the necessary gaskets for the engine type, making it easier for technicians to perform repairs and maintain optimal engine performance.

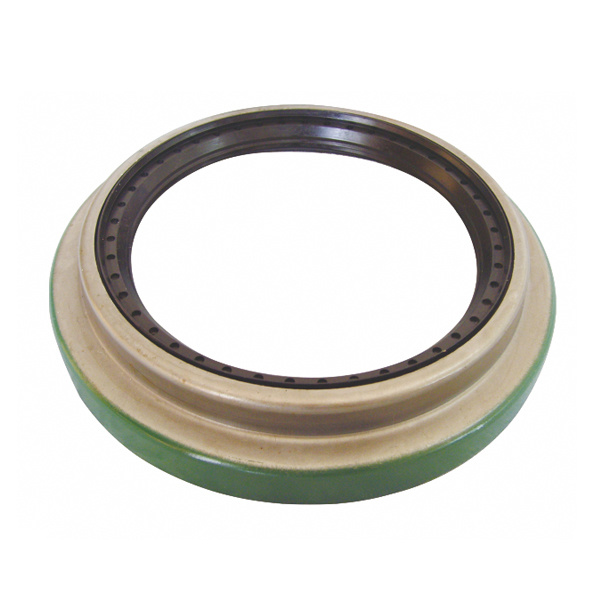

Another essential part of these kits includes seals. Similar to gaskets, seals are designed to prevent fluid leaks within the engine, which is vital for maintaining lubrication and preventing overheating. Having a selection of seals readily available within a repair kit allows for quick replacements during maintenance tasks, minimizing downtime and keeping machinery running smoothly.

Piston rings are also commonly included in an Engine Repair Kit for Heavy Machinery. These rings create a seal between the piston and the cylinder wall, preventing combustion gases from leaking and ensuring efficient engine operation. Over time, piston rings can wear out, leading to a decrease in performance and increased fuel consumption. By having replacement piston rings on hand, maintenance teams can quickly address performance issues and restore engine efficiency.

In addition to gaskets, seals, and piston rings, many repair kits will also contain various fasteners, bearings, and other necessary components that ensure a thorough engine repair. This comprehensive approach saves time and reduces the complexity of sourcing individual parts separately, allowing maintenance professionals to focus on what matters most—keeping the machinery running effectively.

Using an Engine Repair Kit for Heavy Machinery not only simplifies the repair process but also enhances the longevity of the equipment. Regular maintenance and prompt repairs can significantly reduce the risk of catastrophic engine failures, which can lead to costly downtime and repairs. Investing in a quality repair kit means that maintenance teams are better equipped to handle any engine issues that may arise, ensuring the machinery remains reliable and efficient.

In conclusion, an Engine Repair Kit for Heavy Machinery is an invaluable resource for maintenance professionals. By including essential components such as gaskets, seals, and piston rings, these kits streamline the repair process and help maintain optimal engine performance. Ensure that your maintenance practices incorporate a comprehensive repair kit to promote the longevity and reliability of your heavy machinery.

One of the primary components of an Engine Repair Kit for Heavy Machinery is gaskets. Gaskets play a crucial role in preventing leaks between engine components, thereby ensuring the proper functioning of the engine. Over time, gaskets can wear out due to high temperatures and pressure, leading to leaks that can cause significant damage if not addressed promptly. A comprehensive repair kit will often contain the necessary gaskets for the engine type, making it easier for technicians to perform repairs and maintain optimal engine performance.

Another essential part of these kits includes seals. Similar to gaskets, seals are designed to prevent fluid leaks within the engine, which is vital for maintaining lubrication and preventing overheating. Having a selection of seals readily available within a repair kit allows for quick replacements during maintenance tasks, minimizing downtime and keeping machinery running smoothly.

Piston rings are also commonly included in an Engine Repair Kit for Heavy Machinery. These rings create a seal between the piston and the cylinder wall, preventing combustion gases from leaking and ensuring efficient engine operation. Over time, piston rings can wear out, leading to a decrease in performance and increased fuel consumption. By having replacement piston rings on hand, maintenance teams can quickly address performance issues and restore engine efficiency.

In addition to gaskets, seals, and piston rings, many repair kits will also contain various fasteners, bearings, and other necessary components that ensure a thorough engine repair. This comprehensive approach saves time and reduces the complexity of sourcing individual parts separately, allowing maintenance professionals to focus on what matters most—keeping the machinery running effectively.

Using an Engine Repair Kit for Heavy Machinery not only simplifies the repair process but also enhances the longevity of the equipment. Regular maintenance and prompt repairs can significantly reduce the risk of catastrophic engine failures, which can lead to costly downtime and repairs. Investing in a quality repair kit means that maintenance teams are better equipped to handle any engine issues that may arise, ensuring the machinery remains reliable and efficient.

In conclusion, an Engine Repair Kit for Heavy Machinery is an invaluable resource for maintenance professionals. By including essential components such as gaskets, seals, and piston rings, these kits streamline the repair process and help maintain optimal engine performance. Ensure that your maintenance practices incorporate a comprehensive repair kit to promote the longevity and reliability of your heavy machinery.

Engine Repair Kit for Heavy Machinery

RELEVANT INFORMATION

How is the quality of rubber seals controlled?

2023-05-05

The application range of silicone products is very wide, because it is both non-toxic and environmentally friendly, and does not depend on petroleum resources, so there are silicone products in all aspects of our lives, so under what circumstances will it affect the quality of silicone products? .

Analysis of possible production problems and causes of silicone O-rings

2023-05-05

Silicone O-shaped sealing ring is a kind of rubber ring with silicone as raw material and a circular cross-section. Because its cross-section is O-shaped, it is called silicone O-shaped sealing ring.

Transportation and assembly of oil seals

2023-05-05

Do not open the original packaging, pay attention to whether the packaging is damaged, and try to leave the oil seal in the original packaging before assembly.;