Welcome To Know Our Products, We Can Offer You High Quality Products!

Maximize Uptime: Choosing the Right Heavy Equipment Repair Kits for Optimal Performance

2025-12-03

Maximize Uptime: Choosing the Right Heavy Equipment Repair Kits for Optimal Performance

In industries reliant on heavy machinery, the efficiency of operations can significantly impact overall productivity and profitability. Therefore, having the right heavy equipment repair kits is essential for minimizing downtime and ensuring that machinery performs at its best. In this comprehensive guide, we e

Maximize Uptime: Choosing the Right Heavy Equipment Repair Kits for Optimal Performance

In industries reliant on heavy machinery, the efficiency of operations can significantly impact overall productivity and profitability. Therefore, having the right heavy equipment repair kits is essential for minimizing downtime and ensuring that machinery performs at its best. In this comprehensive guide, we explore the factors influencing the selection of heavy equipment repair kits, the types available, and practical tips for maximizing uptime.

Table of Contents

- Understanding Heavy Equipment Repair Kits

- The Importance of Heavy Equipment Repair Kits

- Key Features to Look For in Repair Kits

- Types of Heavy Equipment Repair Kits

- How to Choose the Right Repair Kit for Your Equipment

- Maintenance Tips to Maximize Uptime

- Common Misconceptions About Repair Kits

- Frequently Asked Questions

- Conclusion

Understanding Heavy Equipment Repair Kits

Heavy equipment repair kits are collections of tools and components designed to facilitate the repair and maintenance of machinery, ensuring they remain operational when needed most. These kits typically contain a variety of parts, tools, and sometimes even detailed instructions for specific repairs.

Investing in high-quality repair kits can significantly enhance the efficiency of your operations. Understanding the components of these kits helps you make informed decisions, ensuring that your machines remain in peak condition.

The Importance of Heavy Equipment Repair Kits

In any industry relying on heavy machinery, unplanned downtime can be costly. Whether it’s due to mechanical failure, wear and tear, or improper maintenance, the consequences can be severe. Heavy equipment repair kits play a crucial role in mitigating these risks by allowing quick repairs and maintenance, thus reducing downtime.

**Why Heavy Equipment Repair Kits Are Essential:**

1. **Quick Response Time**: Having a comprehensive repair kit on hand allows operators to address issues immediately, reducing the time machines are out of service.

2. **Cost Savings**: The cost of downtime often outweighs the investment in repair kits. Timely repairs can save significant amounts in operational costs.

3. **Enhanced Safety**: Keeping equipment in proper working order reduces the risk of accidents caused by mechanical failures.

Key Features to Look For in Repair Kits

When selecting heavy equipment repair kits, it’s essential to consider several key features that can enhance their effectiveness:

1. Compatibility with Equipment

The first and foremost criterion is ensuring that the repair kit is compatible with your specific heavy machinery. Different machines may require different parts, tools, and components.

2. Quality of Components

High-quality materials should make up the parts included in the repair kit. Durable materials ensure longevity, reliability, and efficiency during repairs.

3. Variety of Tools and Parts

An ideal repair kit should contain a wide range of tools and components to cover various repair needs. This can include wrenches, sockets, bolts, seals, and more.

4. Detailed Instructions

A good repair kit often comes with user-friendly manuals or guides that provide step-by-step instructions for repairs, making it easier for operators to perform maintenance tasks efficiently.

5. Compact and Portable Design

A repair kit designed for portability can be beneficial, especially if equipment is used across multiple job sites.

Types of Heavy Equipment Repair Kits

Heavy equipment repair kits come in various types, each tailored to different types of machinery and repair needs. Understanding these types can help you choose the right one for your operations.

1. Engine Repair Kits

These kits focus on the engine components, including gaskets, seals, and timing belts. They are essential for maintaining engine efficiency and performance.

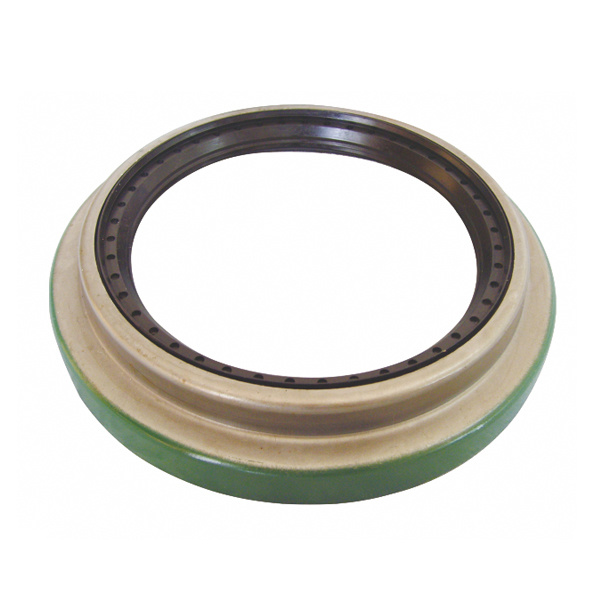

2. Hydraulic Repair Kits

Hydraulic systems are integral to heavy machinery. These kits typically include seals, hoses, and fittings necessary for hydraulic maintenance.

3. Electrical Repair Kits

For equipment with electrical systems, these kits come with wiring, connectors, and other electrical components that may need replacement or repair.

4. General Maintenance Kits

These kits include a comprehensive range of tools and components suitable for various maintenance tasks across different types of equipment.

How to Choose the Right Repair Kit for Your Equipment

Selecting the right repair kit involves several considerations to ensure you make a choice that benefits your operations:

1. Assess Your Equipment Needs

Evaluate the specific machinery you operate and identify the types of repairs you frequently encounter. This will guide you toward the most suitable repair kit.

2. Research Brands and Reviews

Look for reputable brands that have positive reviews from other users in your industry. Recommendations from trusted colleagues can also provide useful insights.

3. Determine Your Budget

While it’s important to invest in quality kits, it’s equally vital to stay within your budget. Compare prices but prioritize quality over cost.

4. Consider Future Maintenance

Think about your long-term maintenance needs. Choosing a kit that can address a variety of potential issues can save you time and money in the future.

Maintenance Tips to Maximize Uptime

To complement the use of heavy equipment repair kits, implementing effective maintenance practices is essential for maximizing uptime.

1. Regular Inspections

Perform routine inspections of machinery to identify potential issues before they escalate into significant problems.

2. Adhere to Maintenance Schedules

Follow manufacturer-recommended maintenance schedules. Consistent upkeep can prolong the life of your equipment.

3. Train Operators Properly

Ensure that operators are trained in the correct use and maintenance of heavy machinery. Proper operation reduces wear and tear.

4. Keep a Well-Stocked Repair Kit

Ensure that your repair kits are stocked with the necessary components to address common issues quickly.

Common Misconceptions About Repair Kits

Understanding the truth behind common misconceptions can help you make better decisions regarding heavy equipment repair kits.

1. “All Kits Are the Same”

Many believe that all repair kits are interchangeable, but this is far from true. Each kit is designed for specific equipment and tasks.

2. “Repair Kits Are Only for Major Breakdowns”

In reality, regular maintenance and minor repairs can often be managed with a repair kit, preventing more significant issues from developing.

3. “Quality Doesn’t Matter”

Some may think that cheaper kits will suffice, but low-quality components can lead to further mechanical issues down the line.

Frequently Asked Questions

1. What should I look for in a heavy equipment repair kit?

Look for compatibility with your equipment, quality of components, variety of tools, and detailed instructions.

2. How often should I perform maintenance on my heavy equipment?

Regular inspections and adherence to the manufacturer’s maintenance schedule are essential for optimal performance.

3. Can I use a general maintenance kit for specific repairs?

While general maintenance kits can address a variety of tasks, specialized kits are better for specific repairs.

4. How can I ensure my repair kit is always stocked?

Conduct regular inventory checks and reorder components as needed to keep your repair kit ready for use.

5. Are cheaper repair kits worth it?

While they may save money initially, cheaper kits often use lower-quality materials that can lead to more significant repairs later, making them less cost-effective.

Conclusion

Choosing the right heavy equipment repair kits is a critical aspect of maintaining operational efficiency and minimizing downtime. By understanding the importance of these kits, evaluating key features, and considering the types available, you can make informed decisions that will ultimately enhance the productivity of your operations. Regular maintenance, proper training, and a well-stocked repair kit will go a long way in ensuring your heavy machinery remains in top condition, maximizing uptime and driving success in your industry.

Heavy Equipment Repair Kits

RELEVANT INFORMATION

How is the quality of rubber seals controlled?

2023-05-05

The application range of silicone products is very wide, because it is both non-toxic and environmentally friendly, and does not depend on petroleum resources, so there are silicone products in all aspects of our lives, so under what circumstances will it affect the quality of silicone products? .

Analysis of possible production problems and causes of silicone O-rings

2023-05-05

Silicone O-shaped sealing ring is a kind of rubber ring with silicone as raw material and a circular cross-section. Because its cross-section is O-shaped, it is called silicone O-shaped sealing ring.

Transportation and assembly of oil seals

2023-05-05

Do not open the original packaging, pay attention to whether the packaging is damaged, and try to leave the oil seal in the original packaging before assembly.;